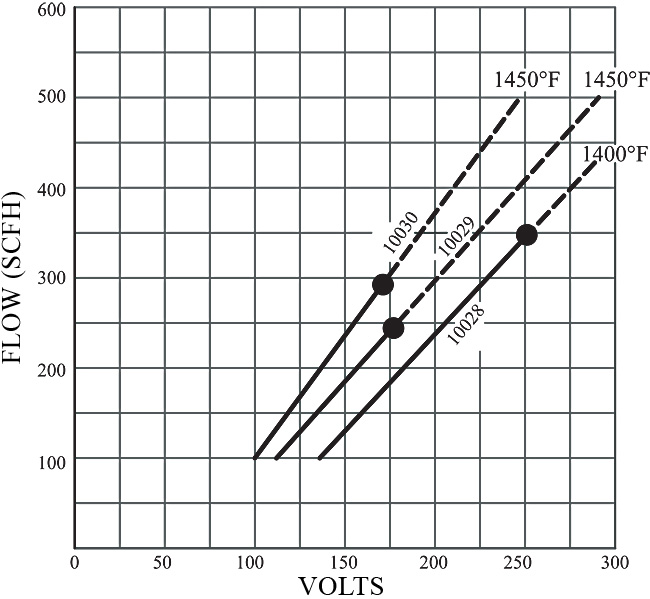

Calculate the SCFM.

Technical Information

Operating Instructions for Flameless Electric Air Heaters

Mounting

Mount heater in desired position. Care should be taken not to restrict exit end of heater. Mechanical shock and vibration should be minimized. Those heaters with quartz envelopes ( ) should be handled with a protective layer of cloth or paper to prevent contamination from finger prints. If quartz is contaminated, it should be cleaned with soap and water or mild solvent prior to operation of heater.

Air Supply

Connect a clean filtered and regulated air source to the inlet air connection of the heater. This air must be free of oils and other forms of contamination to prevent drastic reduction of heater life. A means of regulation is required so that the air flow rate can be adjusted and controlled which will allow maximum heater performance flexibility. A blower capable of operating at 1-2 PSI can be used to supply the 13” housing ( )

Electric Power Connections

Electric connections are made through ¼ x .032 male disconnects provided on Style 001 heaters or through the lead wires provided on

heaters. These connections should be made to the appropriate voltage source by means of a variable transformer so that voltage to the heater can be manually controlled. CONVECTRONICS offers a

which can be used in place of the transformer. This solid state device is rated up to 25 amps and offers infinitely variable phase control. CONVECTRONICS also offers temperature controllers to operate in conjunction with a solid state contactor (with adjustable voltage limiting). Because of the low mass and quick response of these heaters, use only phase angle power control (not zero cross) with

voltage limiting.

and learn more about the specifications for our newest control consoles.

Operation

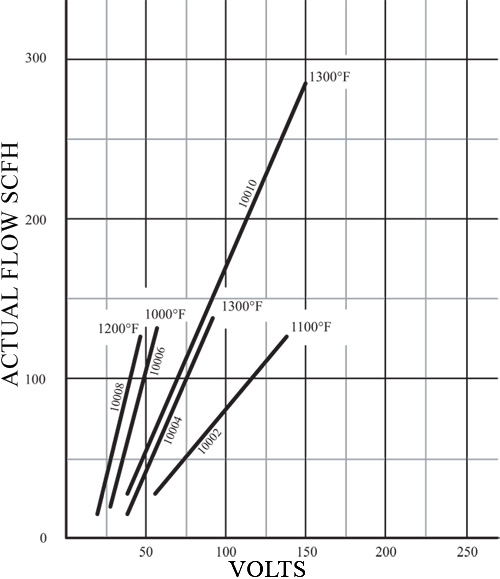

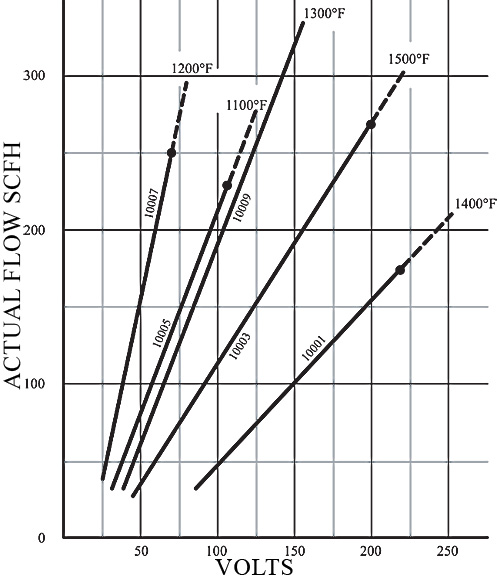

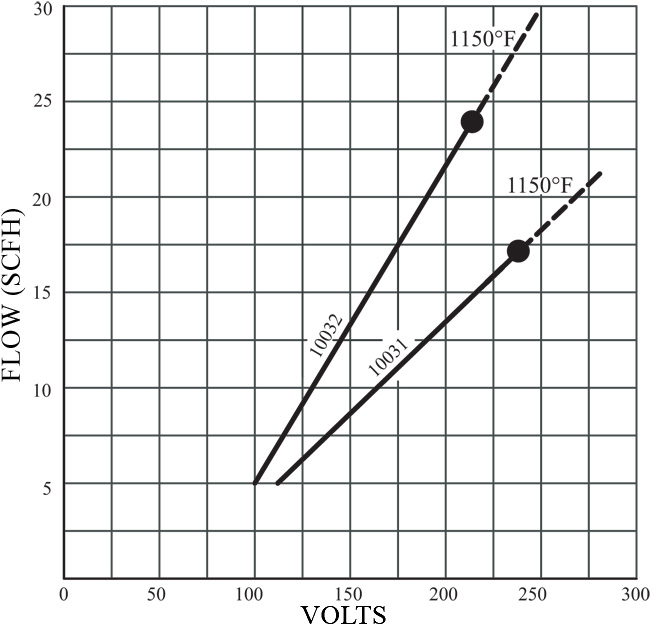

Consult performance curves before operation of heater. Air temperature and ultimately the heater life depend on the heater type, the air flow rate, and the applied voltage. Do not operate beyond the recommended limits. Maximum heater life will occur when the filament temperature does not exceed 1950° F.

Turn on air source and adjust to desired flow rate before applying voltage to heater. Air flow should not be stopped until after power has been turned off and heater has cooled. Pressure switches are available, which can be used to automatically turn off power if air flow is too low or stopped.

Turn on power source and increase voltage until desired temperature is reached. When automatic controls are used, set voltage limiting adjustment so that the maximum voltage does not exceed 100% of the normal steady state value required to maintain the desired conditions. Too high a setting will cause the heater to overshoot, cycle excessively and reduce its life. Do Not use zero cross systems.

When a shield or flare is used with the heater, the heater becomes more efficient and therefore the required power will be 10-20% less than normal.