Calculate the SCFM.

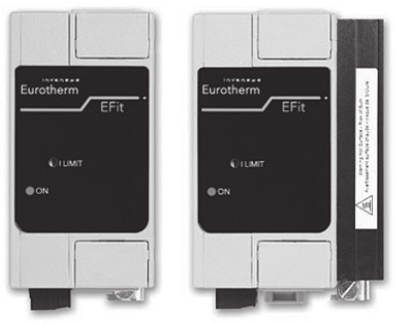

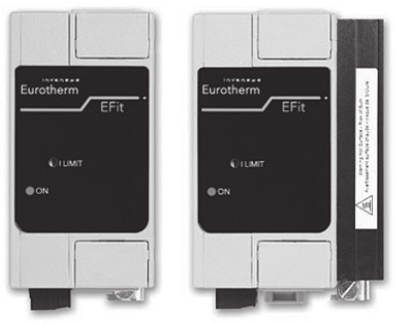

EFIT SCR Power Controllers

The Perfect Fit for Simple Applications

Uncompromising process performance in a cost effective format

Easy to integrate and commission, yet highly cost effective, the EFit power controller provides no compromise control for resistive and infrared heating elements. Ideal for all heating applications and fully compliant to international quality, immunity, and emissions standards, Efit achieves outstanding stable, precise control in the most demanding industrial environments, even when cabinet space is at a premium.

The perfect fit for simple heating applications

Some Industrial processes such as heat treatment require precise temperatures in order to comply with regulations and it is imperative that the workpiece temperature is kept within specific limits. This can be difficult to achieve in industrial plants where the operation of large machinery can cause fluctuations in the voltage supply. In the case of resistive heaters a variation of 10% in the supply voltage will generate a 20% variation in the power to the load, resulting in undesirable temperature fluctuations. EFit contains built in compensation that continues to apply stable power with better than ±2% linearity at the boundaries of the load, even during fluctuations in the supply. The result is a reliable, repeatable heating process and high quality end products compliant to demanding heat treatment standards.

- Connect Easily

— No configuration

— Compact installation

— Global standardization - Control precisely

— Eliminate voltage fluctuations

— Achieve tight tolerances

— Optimise energy use - Improve processes

— Minimise downtime

— Maximise throughput

— Reduce cost of ownership

The perfect fit

Connect Easily

cabinet space makes EFit the perfect fit for power control in both new and retrofit applications.

Easy Installation

- Nothing to configure — plug and play

- Nothing to fix — just clip onto DIN rail

- Minimal connection — pre-wireable plug in connectors

Easy Integration

- Compact dimensions reduce cabinet costs

- Integrates worldwide — global standard approvals and international

voltages - Consistent form factor — same height and depth across the range

- Ideal form and fit drop in replacement for Eurotherm TE10A

Improve Processes

environments, EFit will enable you to run continuously optimised

heating processes with minimum down time. This faster throughput improves OEE (Overall Equipment Effectiveness), helping you achieve

your KPIs (Key Performance Indicators).

Increase throughput

- Maximise utilisation of plant equipment

thanks to fast stable control response

Reduce down time

- Reliably operates in heavy industrial conditions — high immunity to electromagnetic disturbances

- Robust — operates in high temperature, humidity and altitude environments

Control Precisely

Reduce hidden energy costs

- No wasted energy — built in compensation provides stable power control even during power fluctuations, eliminating unexpected changes in heater temperature

- Better power factor— save hidden energy costs with dedicated firing modes for each type of load, including a variety of burst modes that provide an efficient alternative to Phase Angle, such as advanced single cycle firing to reduce flicker in short-wave infrared heaters

Consistently high quality end products that comply to standards

- No scrap or rework - linearity better than ±2% of range, accurately controls heaters and maintains the correct load temperature

Standardize Globally

global environment where industry regulations form an essential part of the engineering supply chain.

- Conformity to cUL directive (Canada and

USA) - CCC exempt: product not listed in catalogue of products subject to compulsory certification

- China RoHS

- CE compliance to power controller product standards

Technical Specifications

| General | |

| Directive : | EMC directive 2004/108/EC Low Voltage Directive 2006/95/EC |

| Safety specification: |

EN 60947-4-3:2000 ( 2000-01-12) |

| EMC emissions specification: | EN 60947-4-3:2000 ( 2000-01-12) + EN 60947-4-3:2000/A1:2006 (2006-12-08) + EN 60947-4-3:2000/A2:2011 (2011-09-02) Class A product |

| EMC immunity specification: | EN 60947-4-3:2000 (2000-01-12) EN 60947-4-3:2000/A1:2006 (2006-12-08) EN 60947-4-3:2000/A2:2011 (2011-09-02) |

| Vibration tests: | EN60947-1 annex Q category E |

| Shock tests: | EN60947-1 annex Q category E |

| Approvals | |

| cUL: | UL60947-4-1A and UL60947-1 |

| CE: | EN60947-4-3 and EN 60947-1 A certificate of conformity can be provided on simple request |

| CCC exempt: | Product not listed in catalogue of products subject to compulsory certification |

| China RoHS: |

Restriction of Hazardous Substances compliant |

| Protection: | IP20, According to EN60529 – CE Open type – UL |

| Condition of use | |

| Atmosphere: | Non-corrosive, non-explosive, non-conductive |

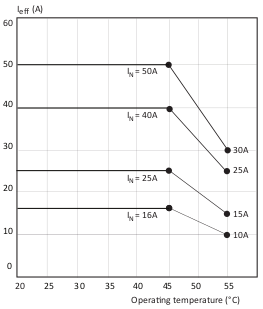

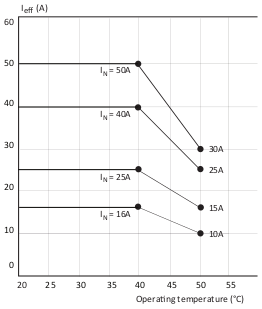

| Operatoring temperature: |

0 to 45°C without derating |

| Storage temperature: |

–25°C to 70°C (maximum) |

| Altitude: |

1000m maximum at 45°C 2000m maximum at 40°C For higher temperature see de-rating curves below |

| Degree of pollution: |

Degree 2 |

| Humidity limits: |

5% to 95% RH (non-condensing) |

|

Current derating curves as a function |

Current derating curves as a function |

| Power | |

| Nominal current: | 16 to 50A |

| Nominal voltage: | 100V to 500V (+10%/–15%). Refer to order code for more details |

| Frequency: | 47Hz to 63Hz |

| Thyristor protection: | High speed fuse |

| Type of loads: | |

| AC51: | Pure resistive |

| AC56a: | Transformer Primary |

| AC55b: | Short wave infra-red |

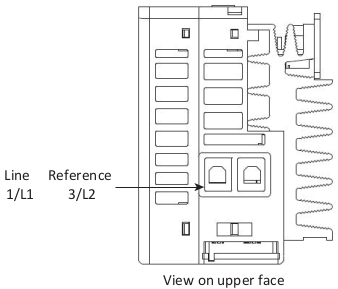

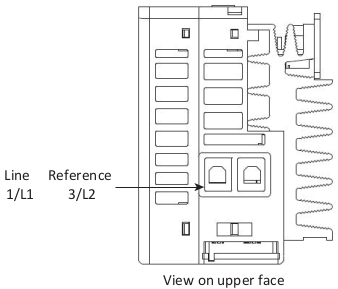

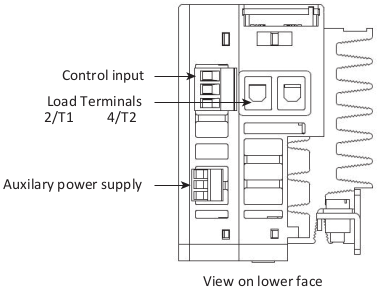

| Power terminals: | Safe cage type, cable size 1.5 to 16mm² tightening torque 2.3Nm (20.4 lb.In) |

| Safety earth screw terminal: | Cable size 1.5 to to 16mm² tightening torque 2.3Nm (20.4 lb.In) |

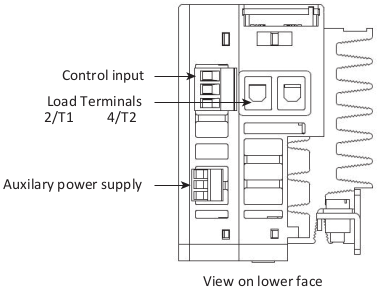

| Control | |

| Supply of electronics: | Self powered product: 100V ac to 500V ac |

| Auxiliary supply: | 115V ac or 230V ac Auxiliary supply must be in phase with the line. The control circuit shall be protected by a ATM2 fuse rated 600V ac/dc, 2A, 100kA |

| Control setpoint: | Either analogue (analogue input or potentiometer) or logic |

| Analogue input signal: | |

|

DC voltage: |

0-5V, 0-10V, Input impedance 100k ohms |

| DC current: | 4-20mA 250 ohms Burden resistor 250 ohms |

| Potentiometer: | A ‘5V user’ voltage is available between terminals 5 and 7 to be used with an external potentiometer of 10Kohm. One potentiometer per unit should be used |

| Logic: | Contact for On/Off logic operation |

| Control terminals | Plug-in connector 0.5 to 2.5mm² (24 to 12AWG) cables Tightening torque 0.6 Nm (5.31 lb.In) |

| Control Performance | |

| Linearity: | Better than ±2% of the full range |

| Stability: | Better than ±2% of the full range with constant resistance Automatic compensation for supply fluctuation (variation: between –10% and +10% of the nominal voltage). |

| Firing modes: | |

| Burst: | Burst variable (16 periods) Single cycle Advanced single cycle |

| Phase angle: | With or without current limit |

|

|

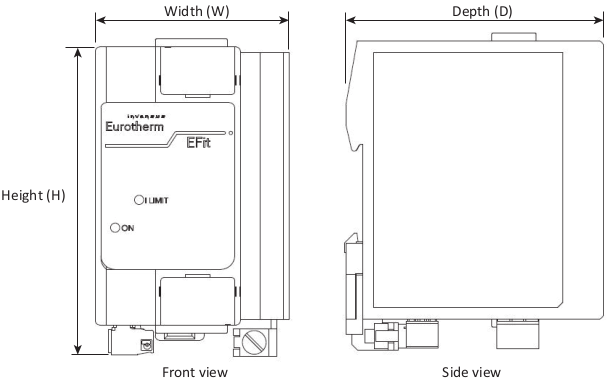

Mechanical Details

| Model | Height | Width | Depth | Weight | Mounting |

| 16A | 115mm | 52.5mm | 92.5mm | 0.55kg | DIN rail |

| 25A | 115mm | 70mm | 92.5mm | 0.7kg | DIN rail |

| 40A | 115mm | 105mm | 92.5mm | 0.9kg | DIN rail |

| 50A | 115mm | 122.5mm | 92.5mm | 1.2kg | DIN rail |

Mounting: DIN rail

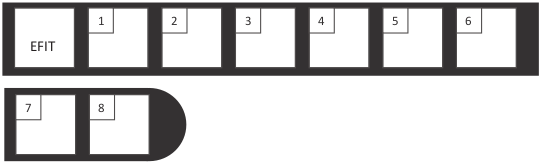

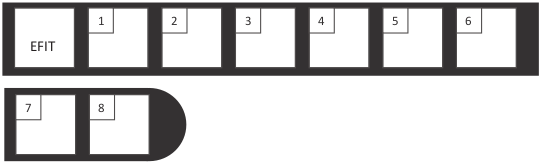

Order Codes

| Basic Product |

| EFIT | Basic SCR Power Controller |

| 1 | Current |

| 16A | 16 amps |

| 25A | 25 amps |

| 40A | 40 amps |

| 50A | 50 amps |

| 2 | Voltage |

| 100V | 100 volts |

| 115V | 115 volts |

| 200V | 200 volts |

| 230V | 230 volts |

| 240V | 240 volts |

| 277V | 277 volts |

| 380V | 380 volts |

| 400V | 400 volts |

| 415V | 415 volts |

| 440V | 440 volts |

| 480V | 480 volts |

| 500V | 500 volts |

| 3 | Input |

| 0V5 | 0–5V dc |

| 4mA20 | 4–20mA |

| 0V10 | 0–10V |

| 4 | Firing Mode |

| FC | Fast cycle |

| FC1 | Single cycle |

| SCA | Advanced single cycle |

| PA | Phase angle |

| 5 | Language |

| ENG | English |

| FRA | French |

| GER | German |

| 6 | Supply |

| SELF | Self-powered |

| 115V | Auxiliary 115V |

| 230V | Auxiliary 230V |

| 7 | Current Limit |

| XX | Without current limit |

| CL | With current limt (only with Phase angle) |

| 8 | Fuse |

| NOFUSE | Without fuse |

| MSFUSE | Fuse with microswitch |

| FUSE | Fuse without microswitch |

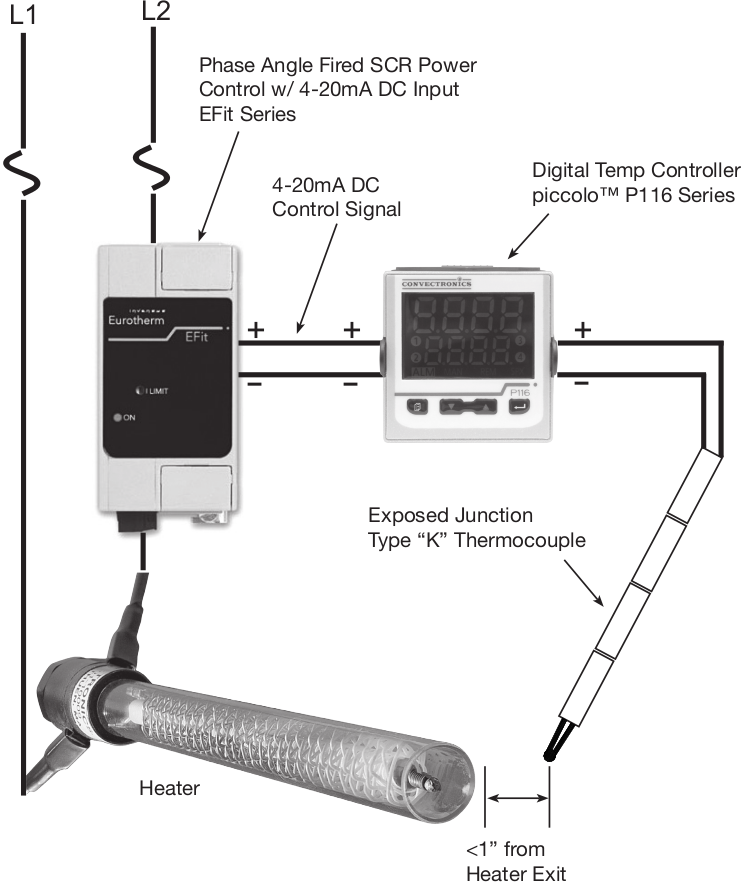

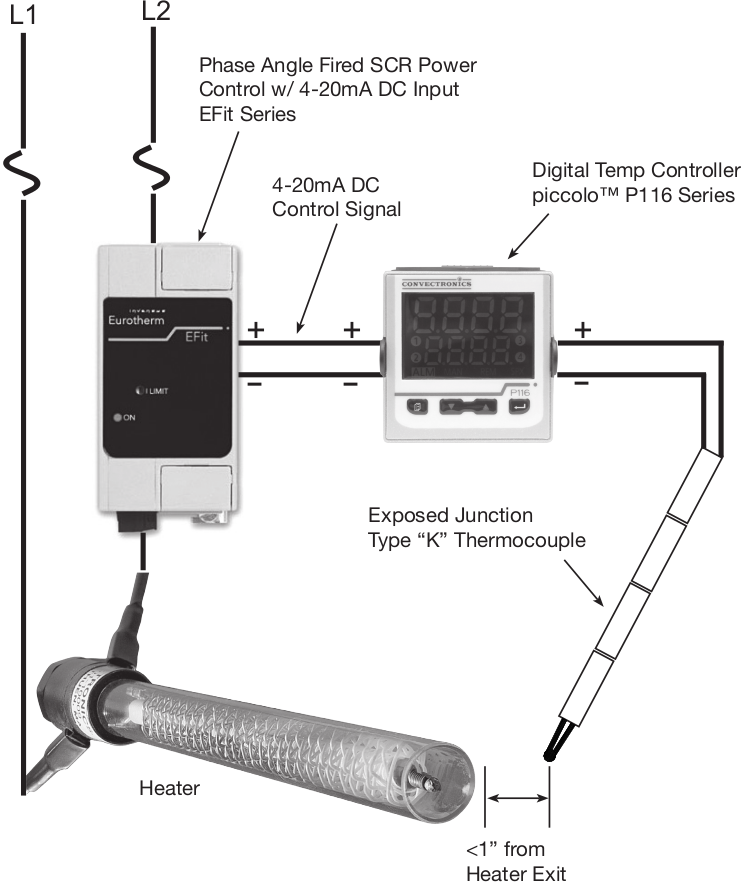

Temperature Controllers:

Process Application Control

Whether it is Open-Loop or Closed-Loop Control, a good Control System is critical for long heater life.*

Here we demonstrate a Closed-Loop (Feedback) Control Set-up ~

Generally considered the optimal method, a closed-loop heater control system uses a power controller, temperature controller, and thermocouple to provide a constant output temperature, regardless of changes in airflow.

*CAUTION -

Only qualified individuals should

wire these installations