Calculate the SCFM.

Forming

Tubular Heater Products

Tubular Electric Heaters - Forming

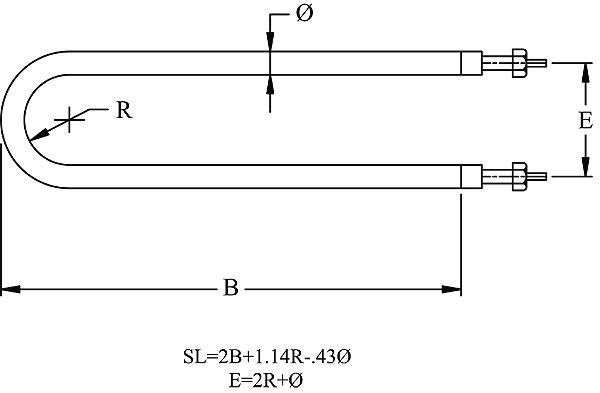

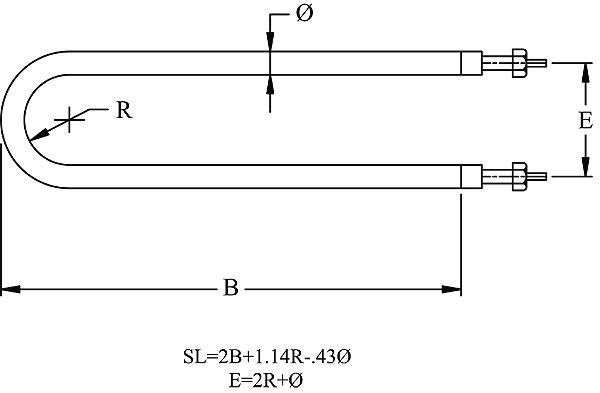

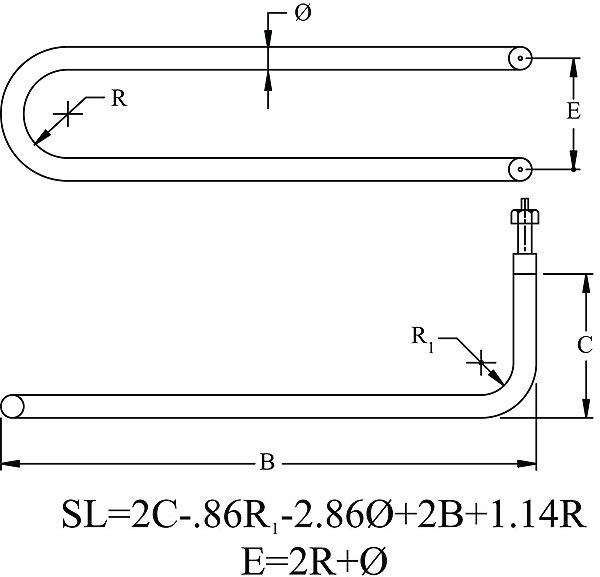

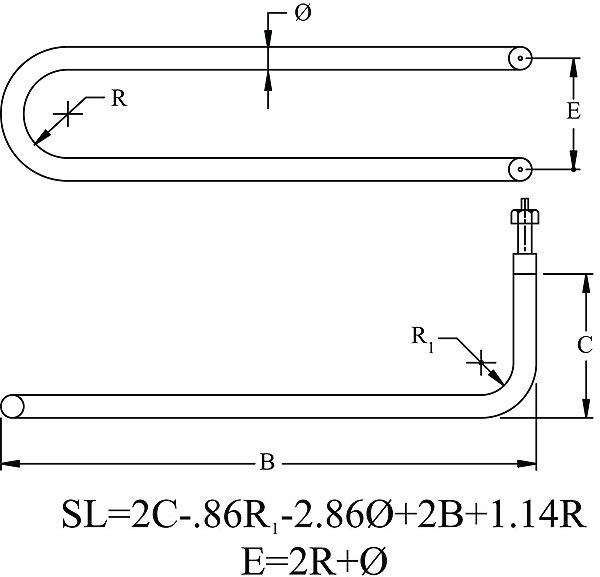

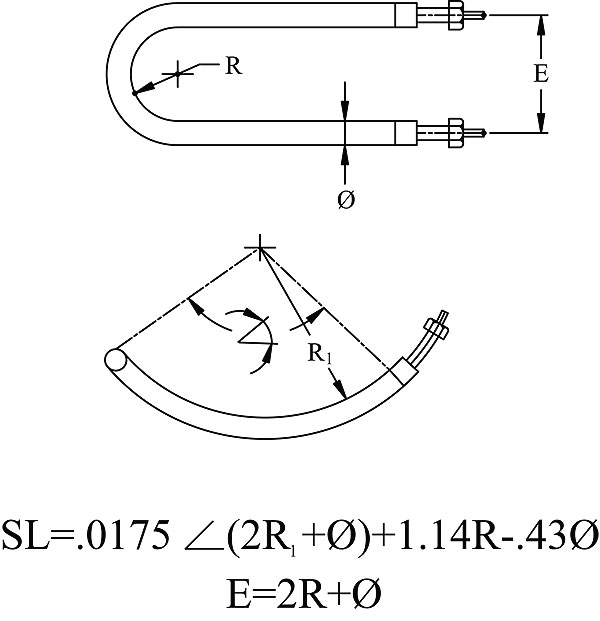

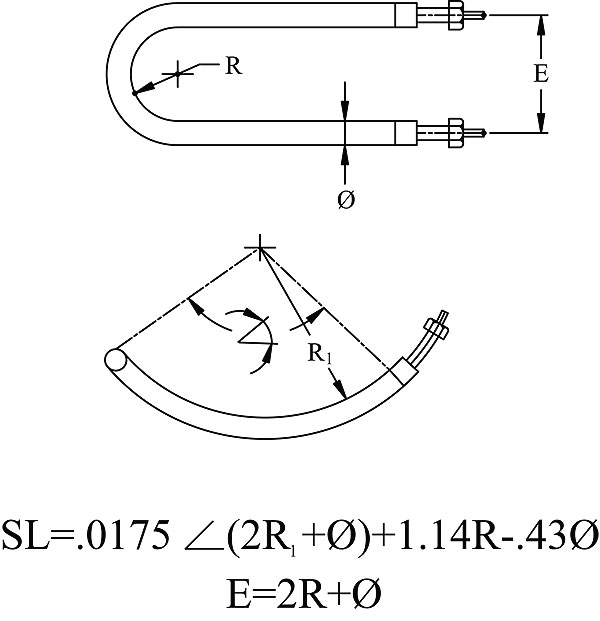

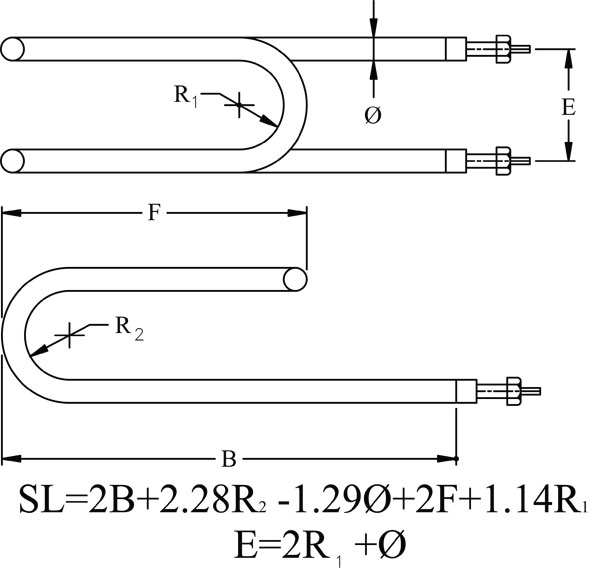

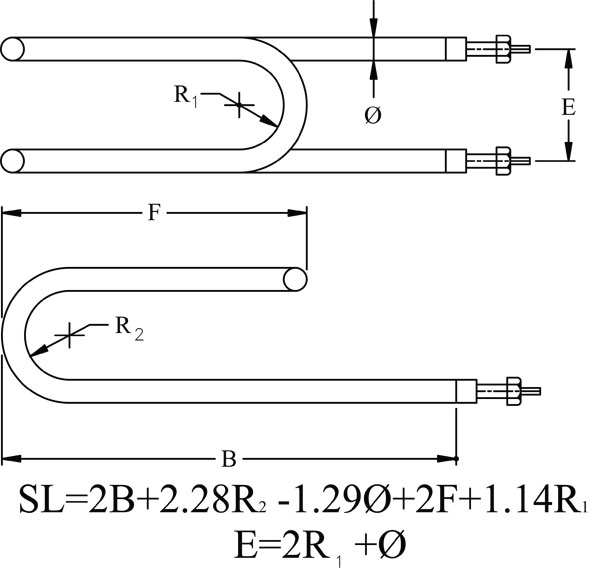

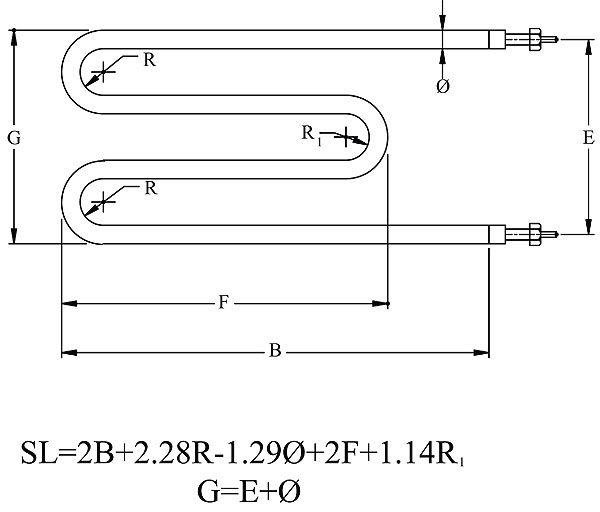

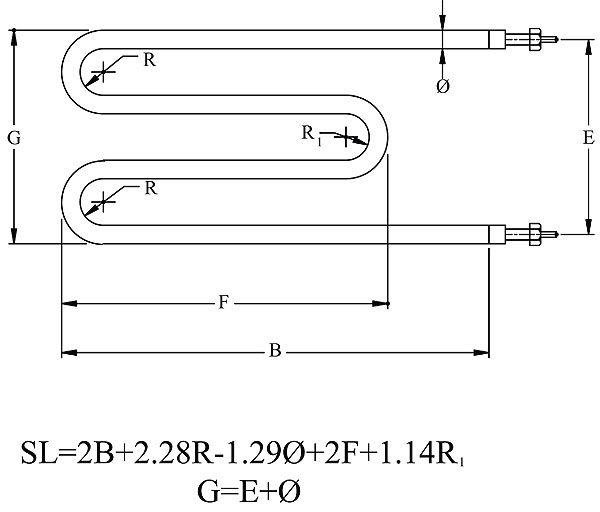

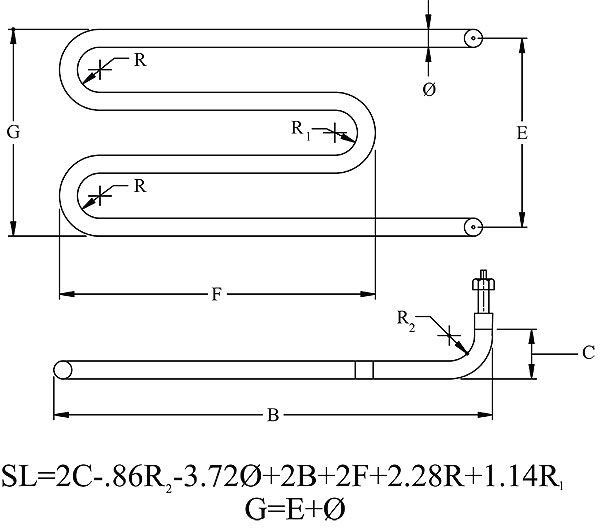

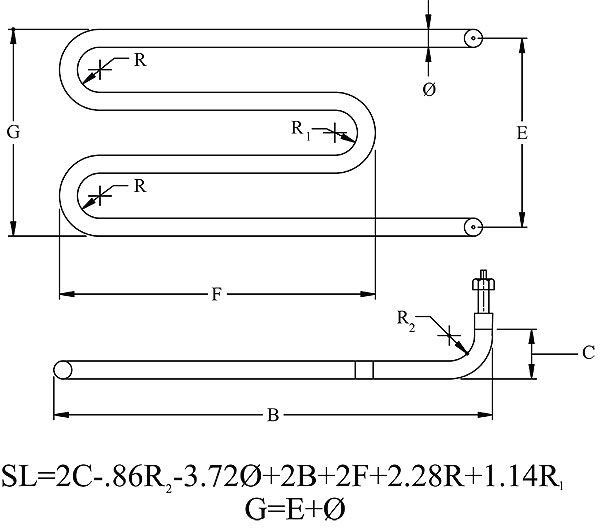

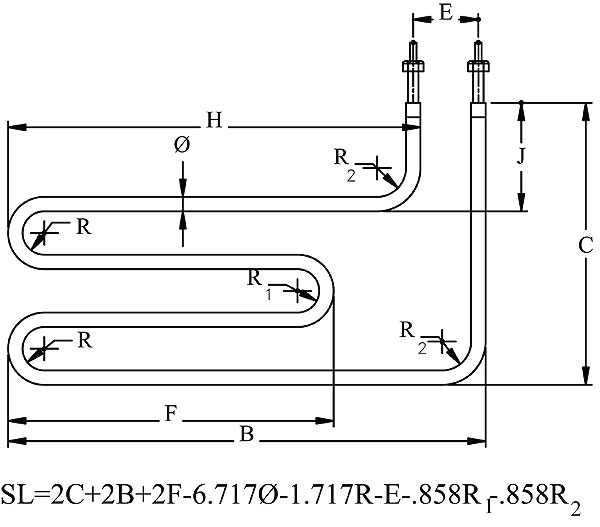

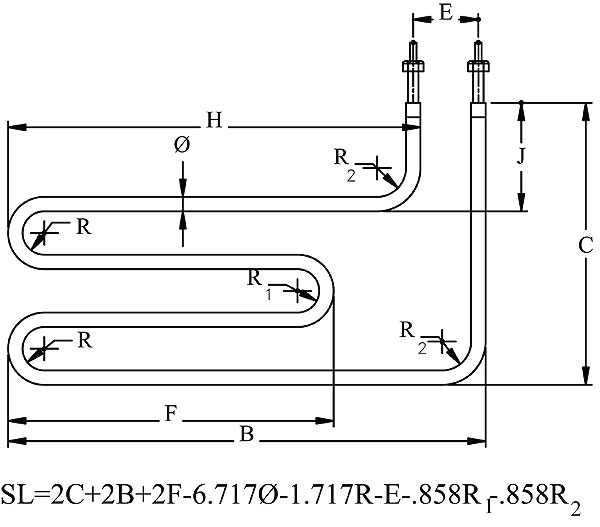

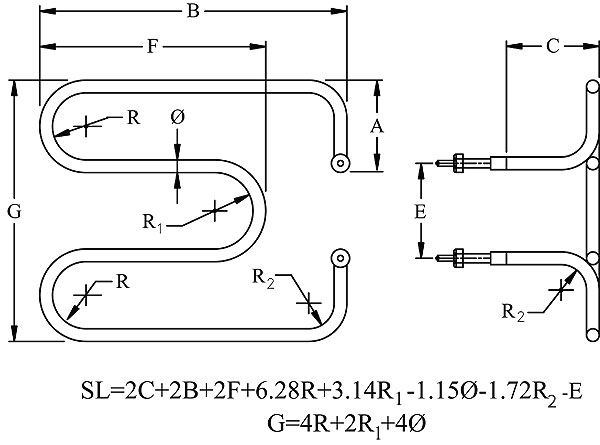

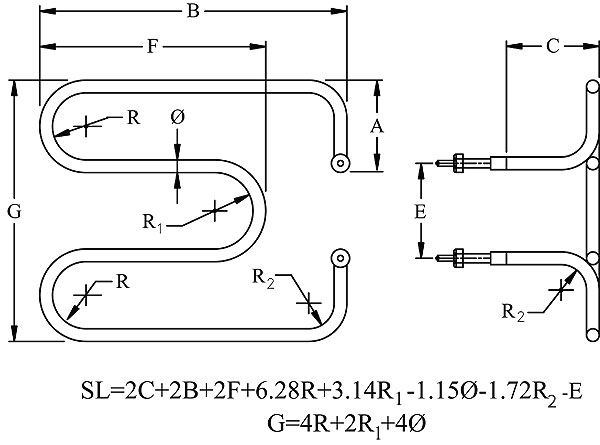

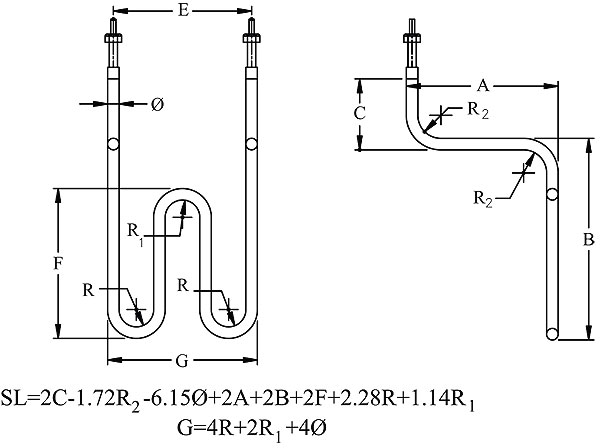

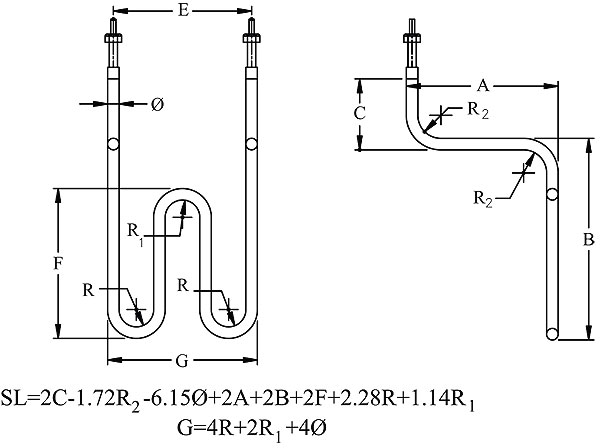

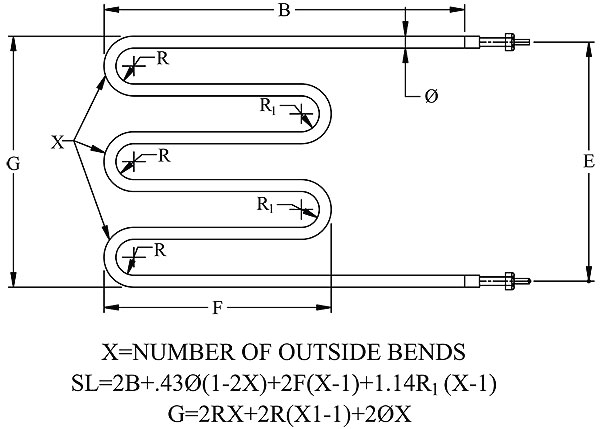

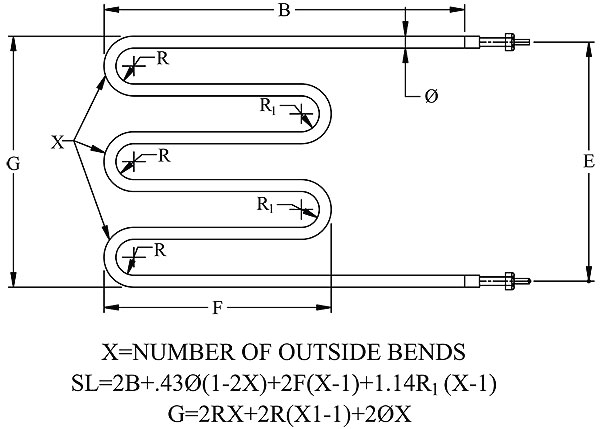

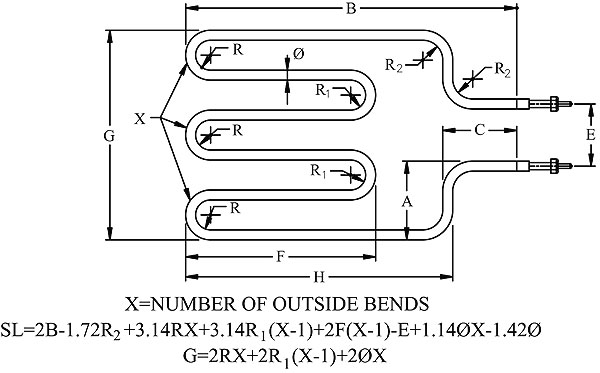

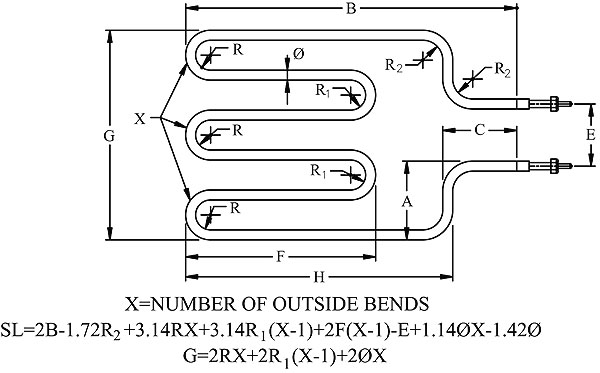

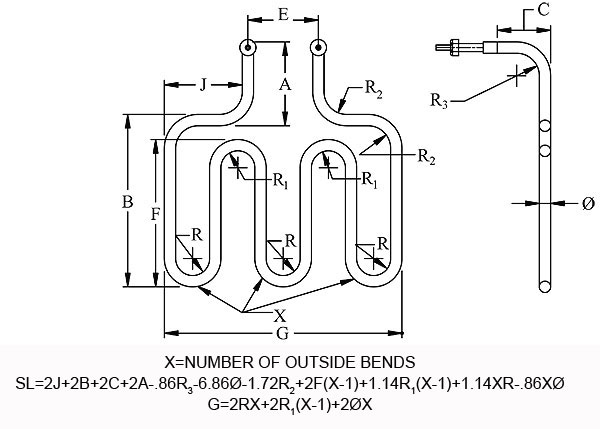

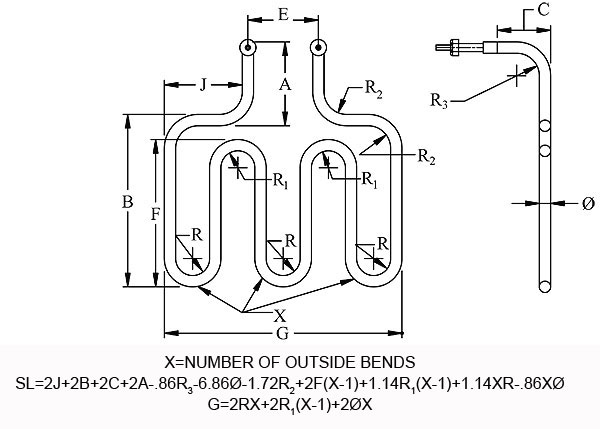

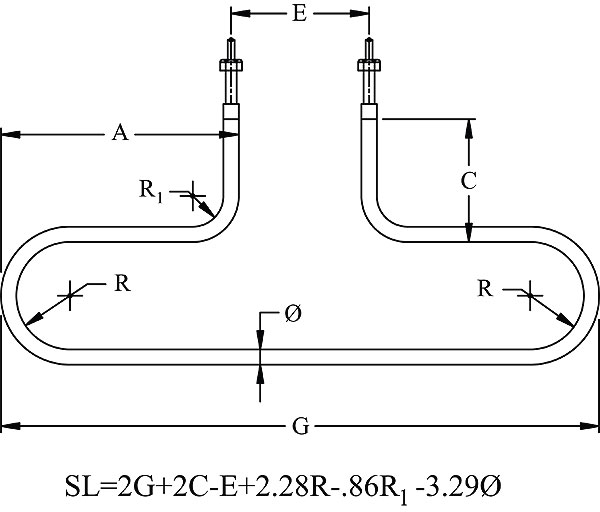

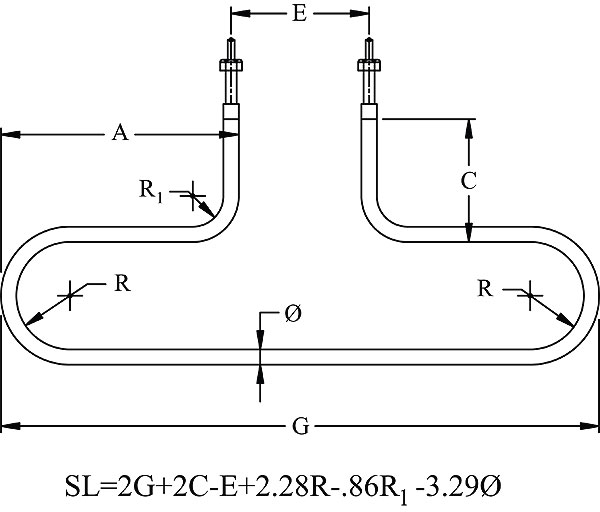

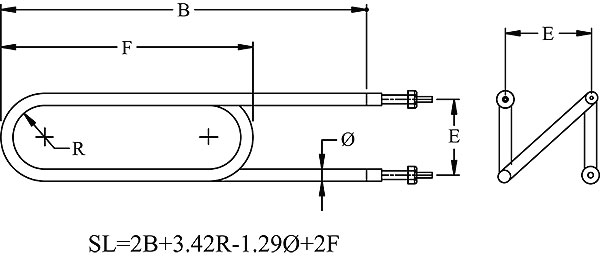

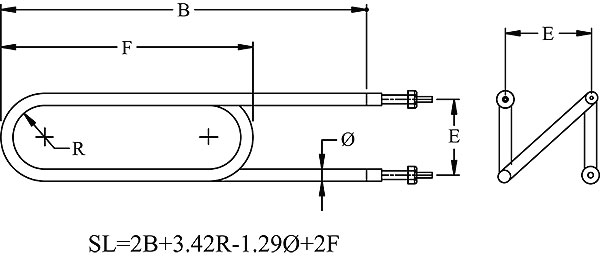

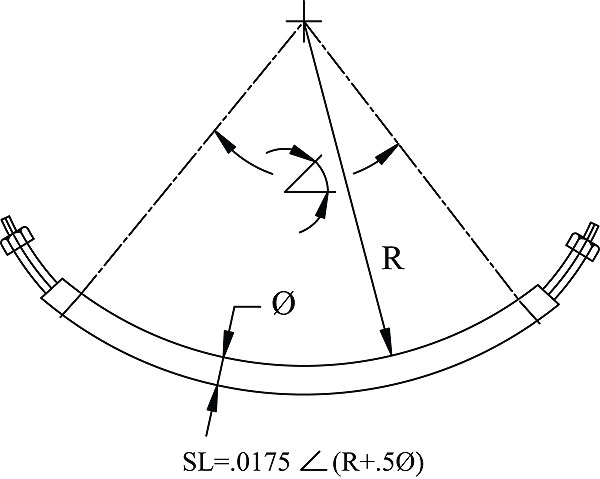

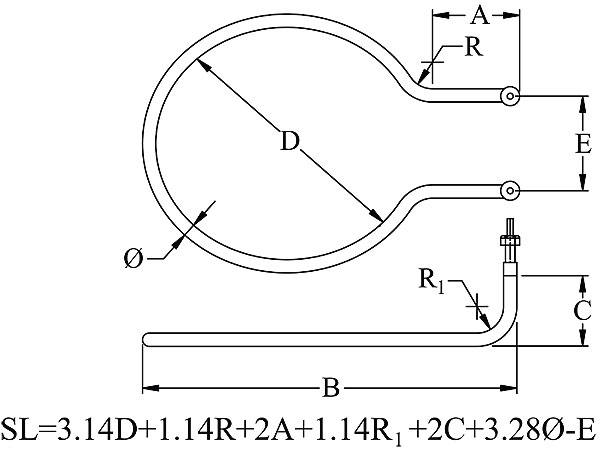

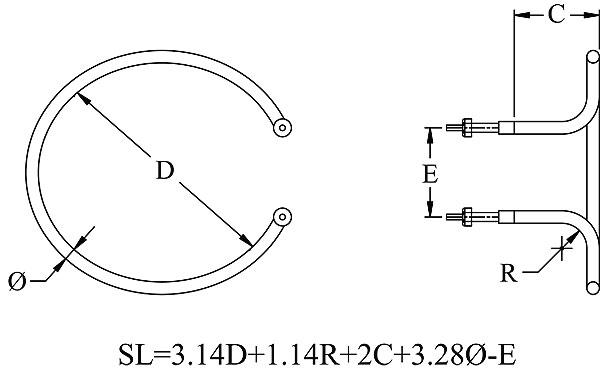

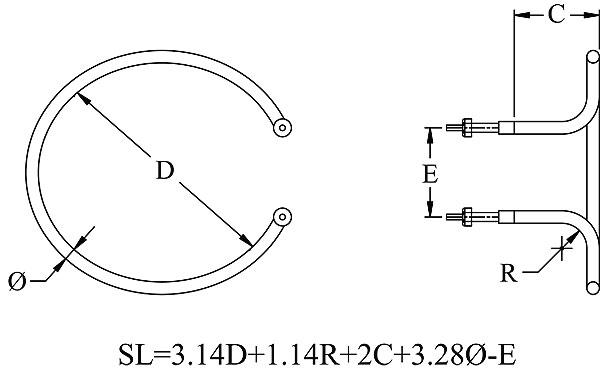

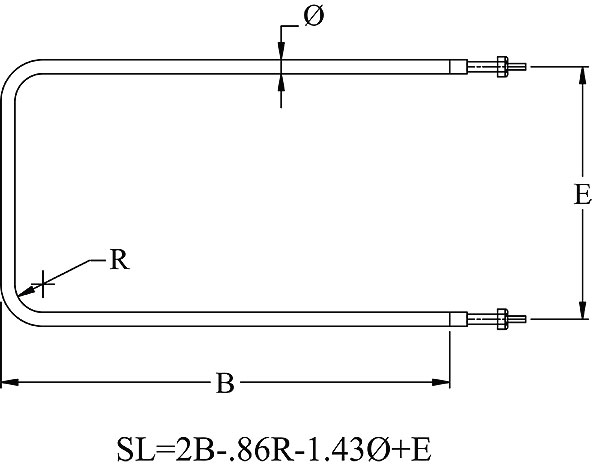

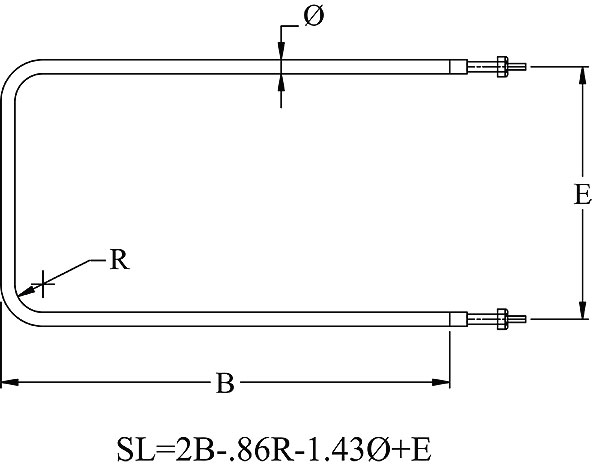

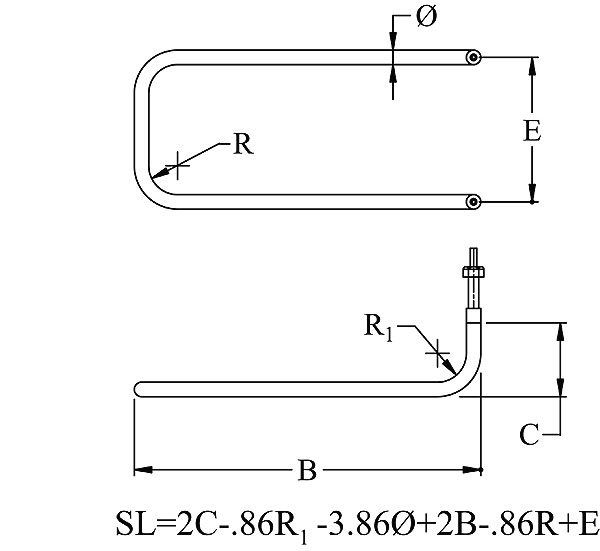

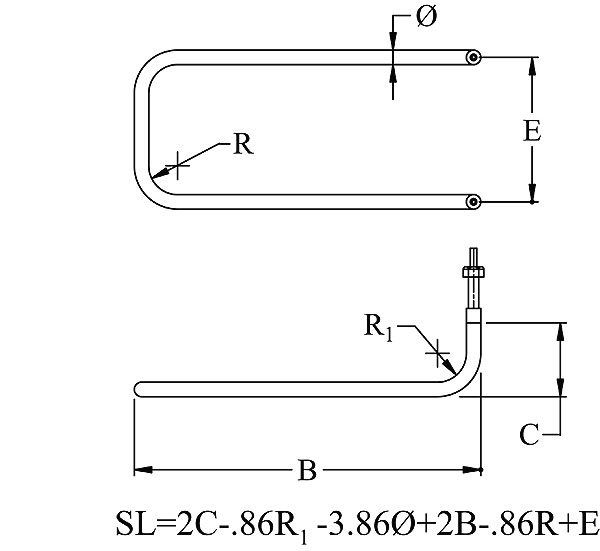

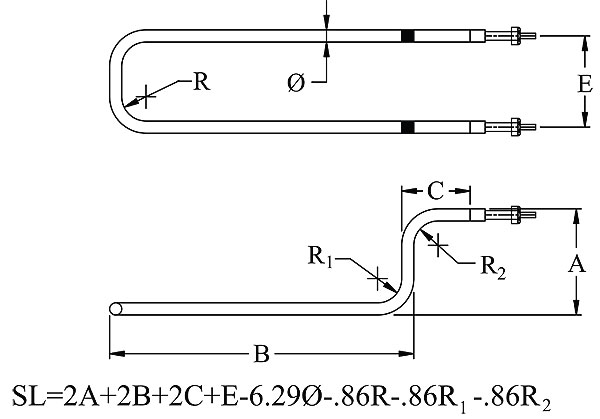

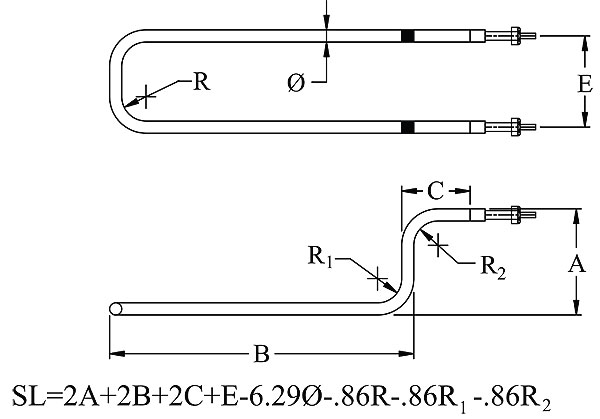

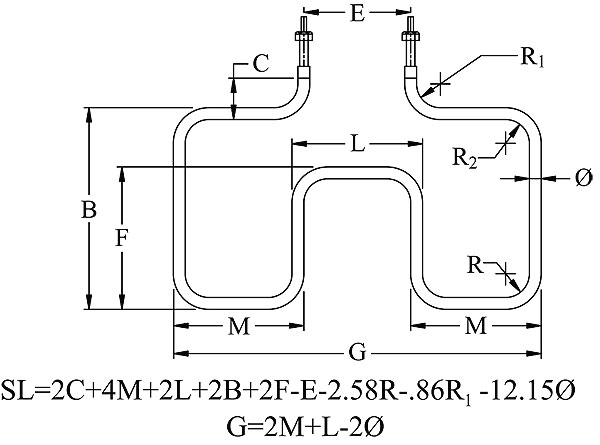

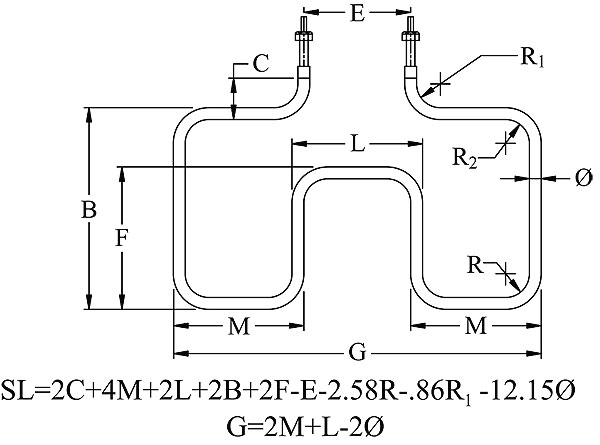

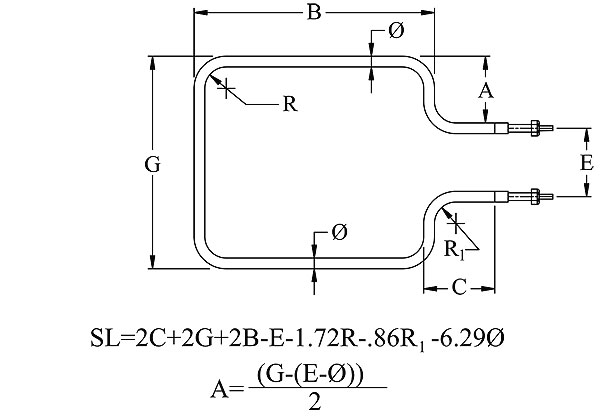

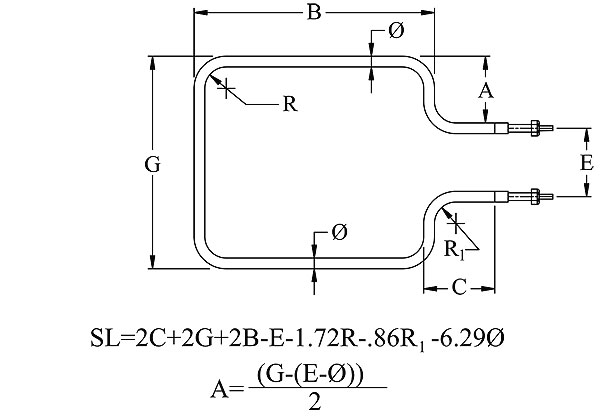

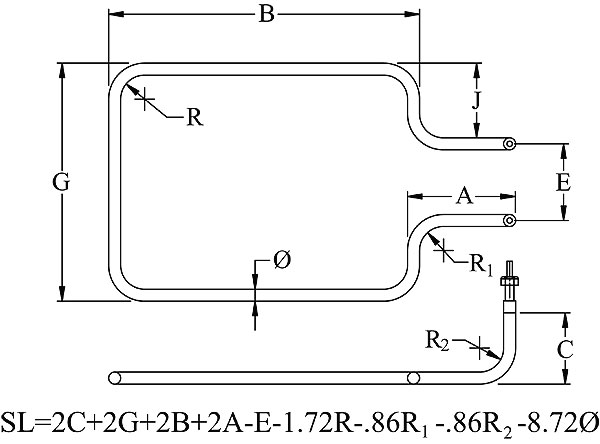

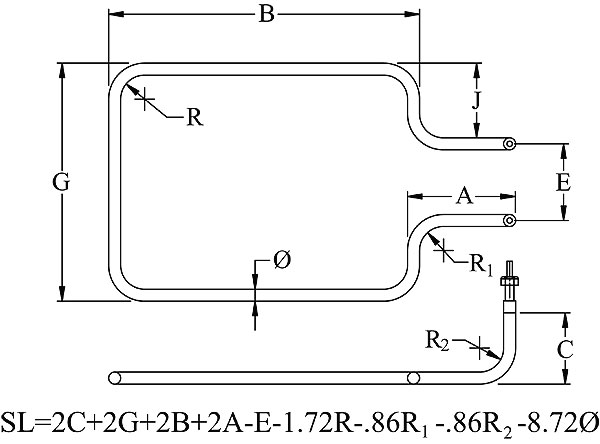

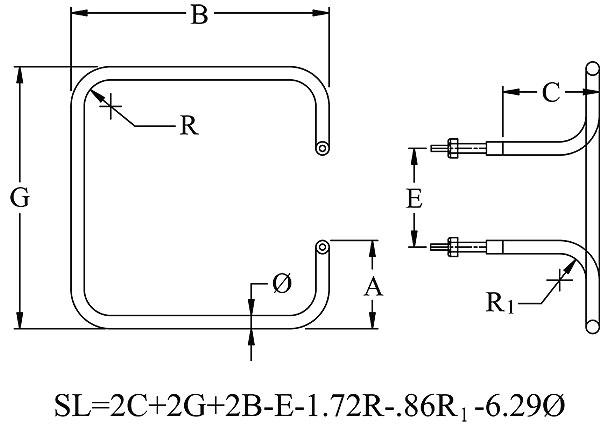

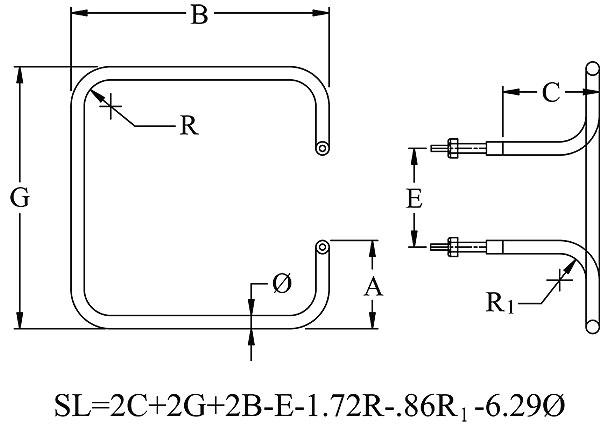

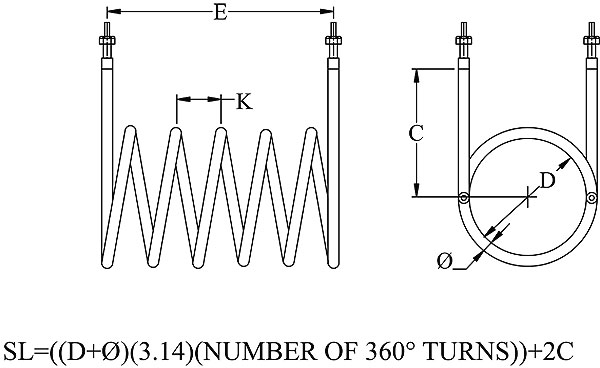

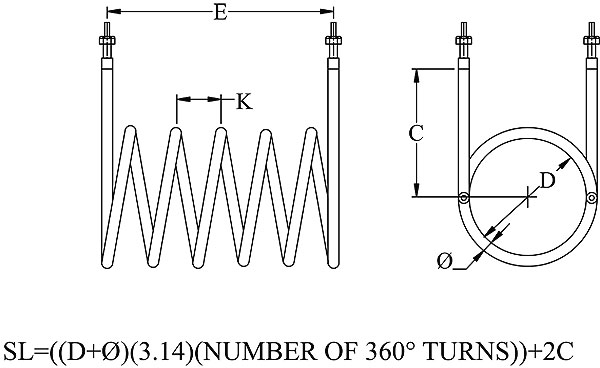

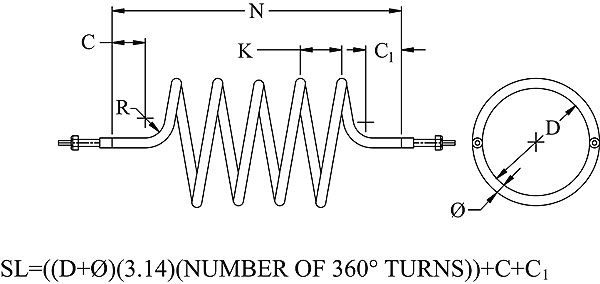

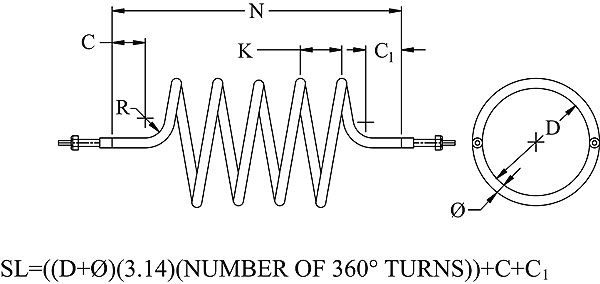

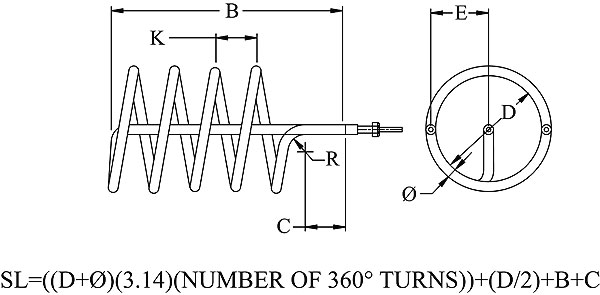

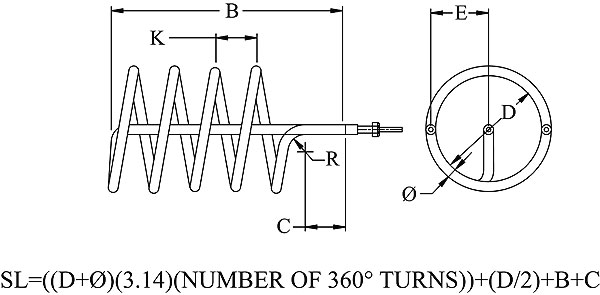

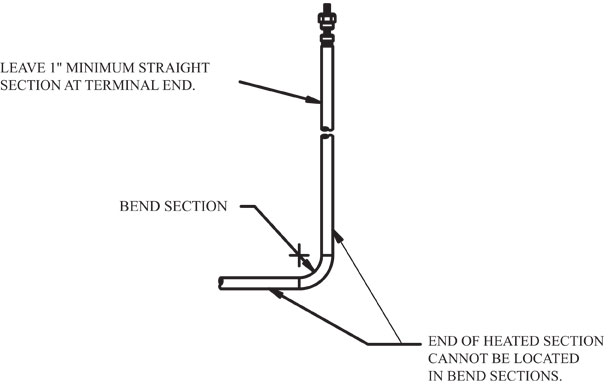

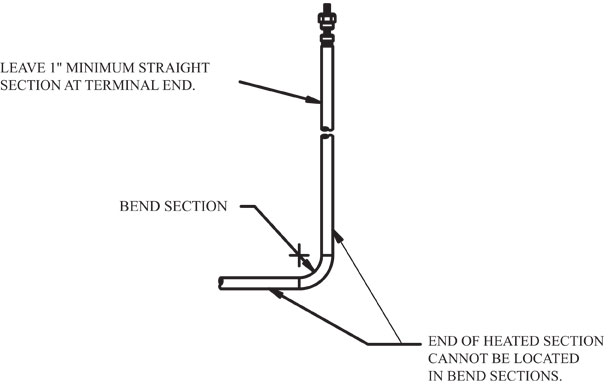

Tubular Electric Heaters can be formed into a multitude of different shapes. Figures BF1 through BF28 are typical of some common designs. For orders or custom design requirements, please specify the dimensions for the figures shown or provide a drawing or sample of the desired shape.

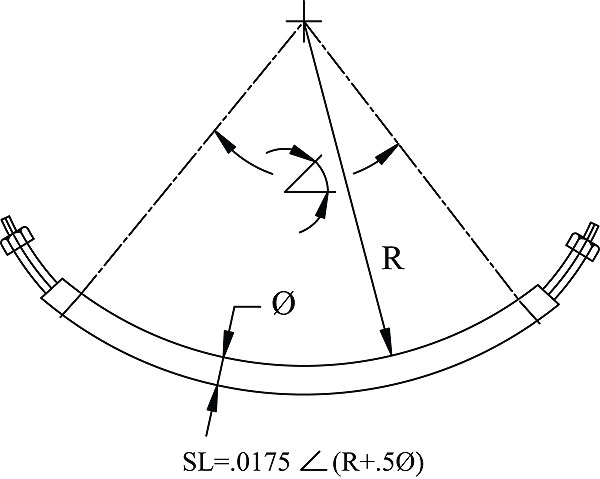

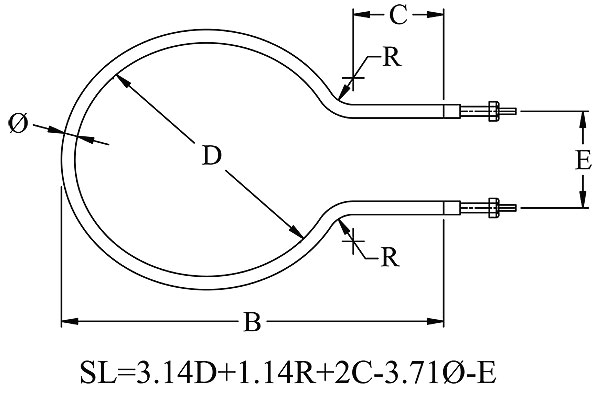

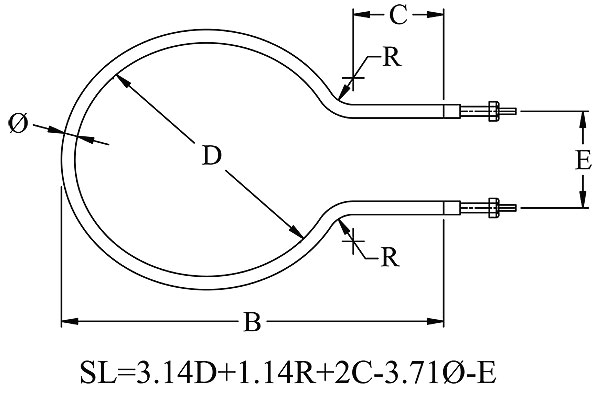

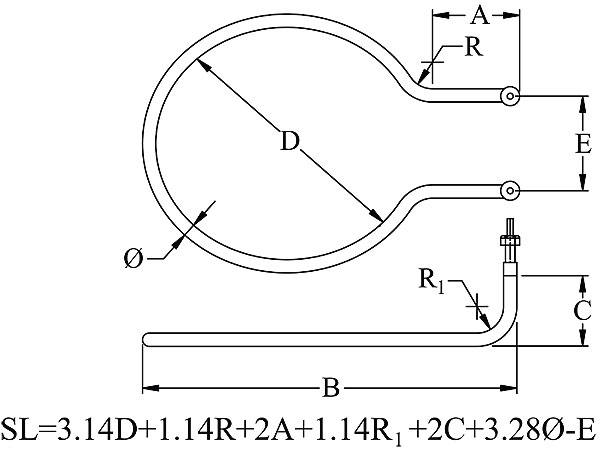

• SL = Sheath Length

• Bends are repressed as required

• Minimum bend radius is equal to the element diameter

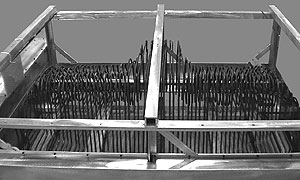

BF1

BF2

BF3

BF4

BF5

BF6

BF7

BF8

BF9

BF10

BF11

BF12

BF13

BF14

BF15

BF16

BF17

BF18

BF19

BF18

BF21

BF22

BF23

BF24

BF25

BF26

BF27

BF28

All Convectronics’ Tubular Heating Elements have the MgO insulation compacted by reducing the element diameter. The elements are then annealed in a furnace to relieve the metal stressing (work hardening) that takes place during the roll reduction of the sheath. Annealing brings the metal back to a soft state, allowing the element to be bent into virtually any configuration. However, forming also work hardens the metal so some precautions must be observed in order to prevent the sheath from breaking during bending or developing stress crack marks.

Note: Elements with tight bends and some applications require the bends to be recompacted in special dies to restore the insulation density and maintain dielectric strength.

Custom Designs

Let our experienced and knowledgeable staff assist you with

Custom Engineering, Design and Implementation of your toughest applications!

Contact CONVECTRONICS for your custom design projects.

Call Toll Free 1‑800‑633‑0166