Calculate the SCFM.

Piccolo Temperature & Process Controllers

piccolo™

Temperature and Process Controller

Standards/Approvals: CE, cUL listed (file ES7766)

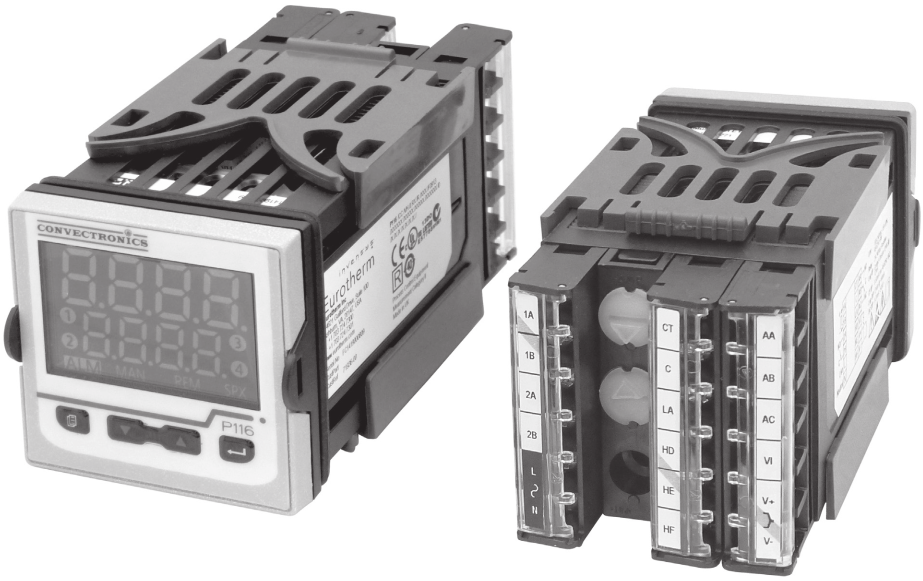

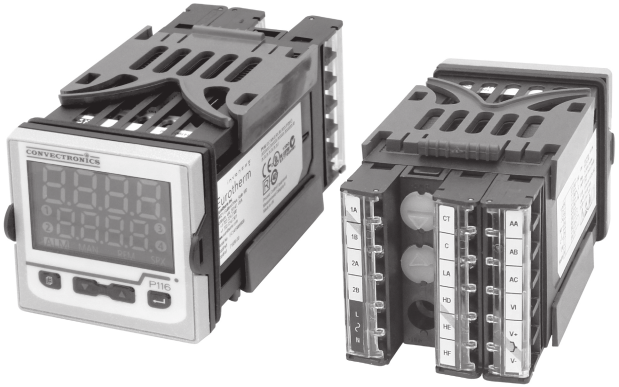

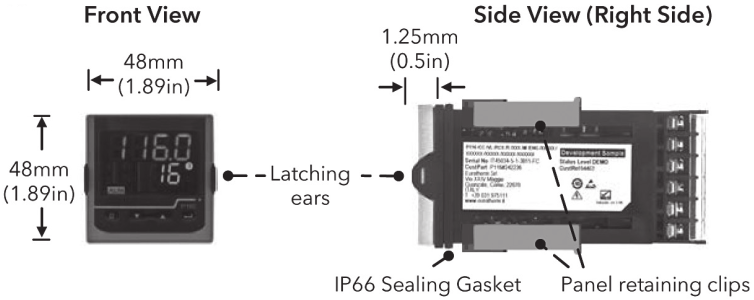

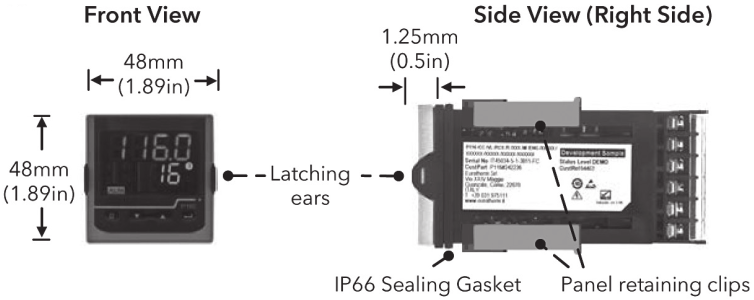

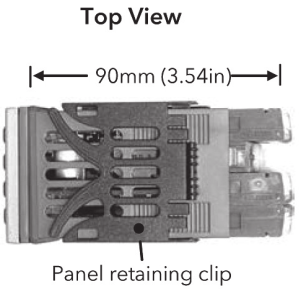

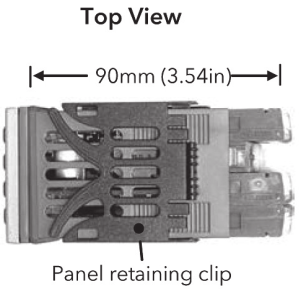

P116 Dimensions

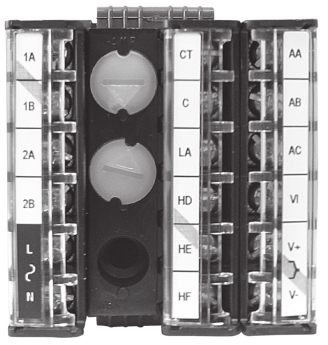

General views of the controllers are shown below together with overall dimensions.

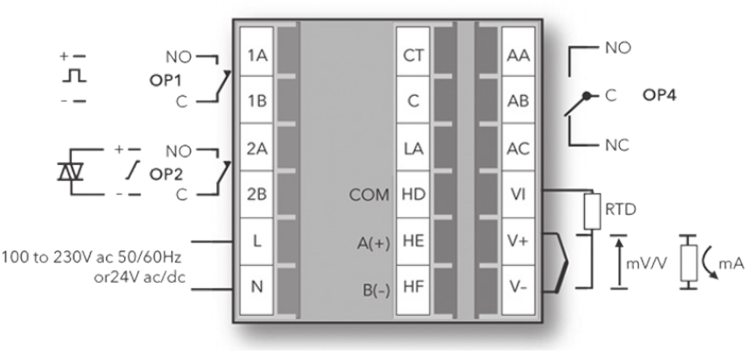

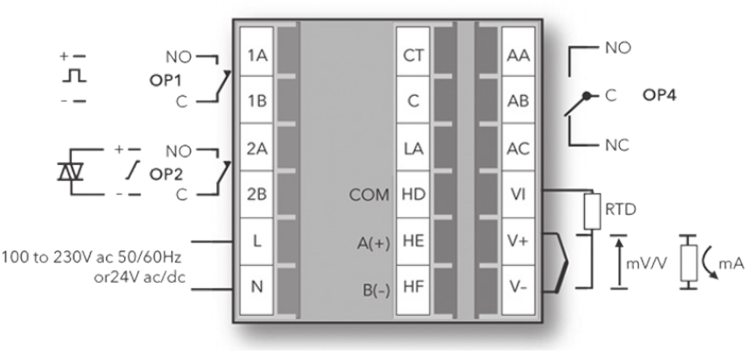

P116 Rear Terminals

Part Number Configurations |

Logic SSR/Relay

Relay/4-20mA

Eurotherm piccolo™ controllers offer precision PID control of temperature and other processes with many advanced features not normally found in this class of controllers.

Designed to offer outstanding performance in an affordable package providing a complete solution for a wide variety of applications, this range guarantees extremely easy access to

parameterization and operation in a high quality unit.

Despite their advanced features, the controllers are easy to use and apply and may be customized for ease of operation. Full autotune is provided.

High quality and high reliabilty

The piccolo controller is a high quality and high reliability

unit from a world leading manufacturer with global

support and service facilities. A 3 year warranty is pro-

vided as standard.

Ramp-soak timer and soft start

A ramp soak timer is provided for time based profiling

of temperature sequences. These can be used to

gradually vary the temperature in a control zone before

maintaining it at a defined level, and is typically used to

avoid the dangers of damage due to thermal shock.

Energy usage estimation

The piccolo controller allows estimation of energy

usage to provide basic data for evaluating energy

saving control strategies for continuous improve-

ment and Kaizen techniques.

Overshoot elimination

The Eurotherm unique cutback system ensures pre-

cise control to setpoint and when correctly tuned

inhibits temperature overshoot.

P116 Rear Terminals

-

Plastic Processing Control

The precision PID controller is used to ensure

uniform heating of the material to avoid material

derogation, undue strain on the extruder

components and improve process reliability.

Can be used to consolidate functions and replace

several interconnected devices to chillers, including

an external timer. -

Incubators

-

Food and Beverage

The simple timer may be used to control

batch operations, e.g., food ovens, fryers

and sterilizers. -

Furnaces, Ovens & Kilns

Well adapted for firing ceramics and heat

treating complex parts. -

Laboratory Equipment

| Environmental Performance | ||

|---|---|---|

| Temperature Limits Operation: | 0 to 60°C | |

| Storage: | -10 to 70°C | |

| Humidity Limits Operation: | 0 to 90% RH non condensing | |

| Storage: | 5 to 90% RH non condensing | |

| Panel Sealing: | IP65 | |

| Shock: | BS EN61010 | |

| Vibration: | 2g peak, 10 to 150Hz | |

| Altitude: | < 2000 meters | |

| Atmospheres: | Not suitable for use in explosive or corrosive atmosphere | |

| Electromagnetic Compatibility | (EMC) | |

| Emissions and Immunity: | BS EN61326 | |

| Electrical Safety | ||

| (BS EN61010): | Installation cat. II; Pollution degree 2 | |

| INSTALLATION CATEGORY II | The rate impulse voltage for equipment on nominal 230V mains is 2500V | |

| POLLUTION DEGREE 2 | Normally, only non-conductive pollution occurs. Occasionally however, a temporary conductivity caused by condensation shall be expected. | |

| Physical | ||

| Panel Mounting: | 1/16 DIN | |

| Weight: | 250g | |

| Panel Cut-Out Dimensions: | 45mm W x 45mm H | |

| Panel Depth: | 90mm | |

| Operator Interface | ||

| Type: | LED | |

| Main PV Display: | 4 digits, green | |

| Secondary Display: | 4 digits, amber | |

| Status Beacons: | Units, outputs, alarms, active setpoint | |

| Power Requirements | 100 to 230 ±15% 48 to 62 Hz, max 6W 24V ac, -15%, +10% 24V dc, -15% + 20% ±5% ripple voltage Max 6W |

|

| Approvals | CE, cUL listed (File ES7766) Suitable for use in Nadcap and AMS2750E applications under Systems Accuracy Test calibration conditions Other standards pending |

|

| Process Variable Input | ||

| Calibration Accuracy: | <±0.25% of reading ±1LSD Quoted over full ambient operating range and for all input linearisation types |

|

| Sample Rate: | 4 Hz (250ms) | |

| Resolution (µV): | <0.5µV with 1.6sec filter | |

| Resolution (effective bits): | >17 bits | |

| Linearisation Accuracy: | <0.1% of reading | |

| Drift with Temperature: | <50ppm (typical) <100ppm (worst case) | |

| Common Mode Rejection: | 48-62 Hz, >-120dB | |

| Series Mode Rejection: | 48-62 Hz, >-93dB | |

| Input Impedance: | 100MΩ | |

| Cold Junction Compensation: | >30:1 rejection of ambient change | |

| Cold Junction Compensation: | >30:1 rejection of ambient change | |

| Cold Junction Compensation: | >30:1 rejection of ambient change | |

| Cold Junction Accuracy: | <±1°C at 25°C ambient | |

| Linear (process) Input Range: | -10 to 80mV, 0 to 10V with 100K/806 external divider module | |

| Thermocouple Types: | K, J, N, R, S, B, L, T, C | |

| Resistance Thermometer Types: | 3-wire Pt100 DIN 43760 | |

| Bulb Current: | 0.2mA | |

| Lead Compensation: | No error for 22 ohms in all leads | |

| Input Filter: | Off to 59.9s | |

| Zero Offset: | User adjustable over full range | |

| User Calibration: | 2-point gain & offset | |

| OP 4 Relay | ||

| Type: | Form C (changeover) | |

| Rating: | Min 100mA @ 12V dc, max 2A @ 264V ac resistive | |

| Functions: | Control outputs, alarms, events | |

| Logic Output Module | ||

| Rating: | ON 12V dc @ <44mA; OFF <300mV @ 100µA | |

| Isolation: | None from PV or system, 264V ac double insulated from PSU and communications | |

| Functions: | Control outputs, alarms, events | |

| Relay Output Channels | ||

| Type: | Form A (normally open) | |

| Rating: | Min 100mA @ 12V dc, max 2A @ 264V ac resistive | |

| Functions: | Control outputs, alarms, events | |

| Analogue Output - OP2 | Voltage output can be achieved by external adaptor | |

| Rating: | 0-20mA into <500Ω | |

| Accuracy: | ±(<1% of Reading + <100µA) | |

| Resolution: | 13.5 bits | |

| Isolation: | 264V ac double insulated from PSU and communications | |

| Functions: | Control outputs, retransmission | |

| Software Features - Control | ||

| Number of Loops: | 1 | |

| Loop Update: | 250ms | |

| Control Types: | PID, ON/OFF | |

| Cooling Types: | Linear, fan, oil, water | |

| Modes: | Auto, manual, standby | |

| Overshoot Inhibition: | High, low | |

| Software Features - Alarms | ||

| Number: | 3 | |

| Type: | Absolute high & low, deviation high, low or band | |

| Latching: | Auto or manual latching, non-latching | |

| Output Assignment: | Relay and digital output | |

| Other Status Outputs - Functions: | Including sensor break, timer status, loop break, heater diagnostics | |

| Timer - Modes: | Dwell when setpoint reached; Delayed control action, Soft start limits power below PV threshold | |

| Current Monitor - Alarm Types: | Over current, SSR short circuit, SSR open circuit | |

| Current Monitor - Indication Type: | Flashing Beacon | |

| Special Features: | Energy monitoring, recovery point | |