Calculate the SCFM.

Tubular Heater Products

Tubular Electric Heaters

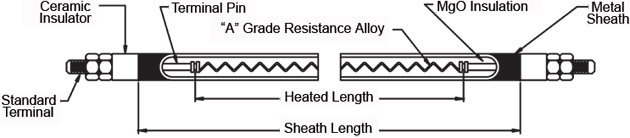

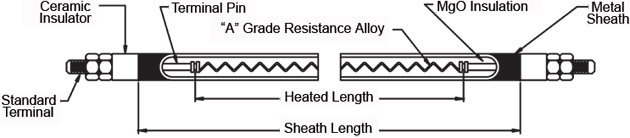

Convectronics’ Tubular Electric Heaters, with their unique and durable construction, are extremely versatile as they can be formed into nearly any configuration. With the broad selection of materials and terminations, combined with a wide range of ratings and sizes, Convectronics’ Tubular Electric Heaters are extremely adaptable to a wide range of industrial, scientific, and commercial applications.

Our heater design consists of a helical coil of nickel-chromium resistance wire that is precisely centered in a metal sheath. Vibration loaded magnesium oxide powder is added into the sheath, insuring even density distribution throughout its length. The entire assembly is then reduced to its finished diameter, therefore compacting the MgO, ensuring that the coil maintains its precise centering in the heater. Lastly, the sheath can be fully annealed for factory or field bending.

Sheath Material

Sheath material selection should be made based on the chemical composition of the solution being heated, the classification of the materials entering the solution, the application and the process controls used. Common sheath materials used are:

Incoloy®800: Resistant to high temperature oxidation and carburization

Common Uses: Air Heating, Radiant Heating, Cleaning & Degreasing Solutions, Plating Solutions & Corrosive Liquids

Stainless Steel: Types 304, 316 and 321

Common Uses: Food Processing Equipment & Corrosive Liquids

Steel: Low carbon, mid-range temperature applications

Common Uses: Oil Immersion, Alkaline Cleaning Solutions, Asphalt & Tar

Copper: Inexpensive alternative for low temperature applications

Common Uses: Water Heating & Freeze Protection

| Electrical Limits | ||||

|---|---|---|---|---|

| Sheath Diameter | .250” | .312” | .375” | .430” |

| Minimum Ohms/inch | .100 | .060 | .040 | .040 |

| Maximum Ohms/inch | 17 | 21 | 21 | 21 |

| Maximum Voltage | 250 | 250 | 480 | 600 |

| Maximum Amperes | 15 | |||

| Wattage Tolerance | +5%-10% @ Rated Voltage | |||

| Resistance Tolerance | +10% -5% | |||

| Resistance Tolerance | +10% -5% | |||

| Sheath Material | Maximum Sheath Temp. |

Maximum Watts per sq. inch |

|---|---|---|

| Incoloy®800 | 1600°F/870°C | 40 |

| Stainless Steel | 1200°F/650°C | 30 |

| Steel | 750°F/400°C | 22 |

| Copper | 350°F/175°C | 55 |

| Sheath Diameters .250" .312" .375" .430" | ||||

|---|---|---|---|---|

| Max. Sheath Length @ given Diameter | 128" | 118" | 118" | 110" |

| Sheath Length Tolerance | +/- 1/8” | |||