Calculate the SCFM.

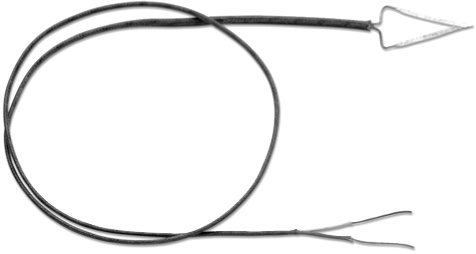

Temperature Sensors

Constructing the Perfect Temperature Sensor

Constructing the perfect Temperature Sensor is a difficult task, but with some planning and the assistance of material specification tables and process application guides, most applications can be matched with a temperature sensor that will provide good temperature measurement and a useful life.

Information contained here and in the Technical Information Section of this catalog will provide you with basic operating principles, thermocouple material specifications, material tolerances, and recommended temperature limits. Also found in the these sections are protection tube material specifications, temperature limits and process application guides that are critical to your selection process. Materials are selected based on the process temperature range and the process environment in which the sensor will be used.

Helpful Hints

- Select your element wire gauge as follows: as large as possible for the longest element life or as small as possible for the fastest time response.

- Thermocouple elements used at temperatures higher than what is recommended for their wire gauge will have a drastically reduced useful life.

- Do not use unprotected type K elements around the presence of sulfur or with protection tubes that have not been degreased. Cutting oils contain sulfur and will cause the element to “green-rot” when exposed to elevated temperatures.

- Do not use platinum thermocouple elements in a metal protection tube without using an inner ceramic protection tube, as the metal will contaminate the platinum.

- Do not use open ended protection tubes with the thermocouple exposed where the element would be exposed to a harmful process environment. For example, type J thermocouples exposed to moisture will allow the iron to rust and deteriorate very rapidly.

- Ceramic and Silicon Carbide protection tubes are all somewhat subject to thermal shock, and all should be preheated prior to inserting into a high temperature process.

- Incinerator applications, because of the high temperatures and harmful high velocity gases normally experienced, require high temperature rated and gas tight protection tubes.

- Do not use Molybdenum or Tantalum sheathed thermocouples in oxidizing atmospheres. They will evaporate within minutes!

- Welded on NPT bushings must be a larger NPT size than the NPT size of the protection tube onto which the bushing is being welded.

- Recommended minimum sensor immersion length is equal to 10 times the diameter of the sensor sheath or protection tube.