Calculate the SCFM.

Contactors & Controllers

The Perfect Fit for Simple Applications

Uncompromising process performance in a cost effective format

Easy to integrate and commission, yet highly cost effective, the EFit power controller provides no compromise control for resistive and infrared heating elements. Ideal for all heating applications and fully compliant to international quality, immunity, and emissions standards, Efit achieves outstanding stable, precise control in the most demanding industrial environments, even when cabinet space is at a premium.

The perfect fit for simple heating applications

Some Industrial processes such as heat treatment require precise temperatures in order to comply with regulations and it is imperative that the workpiece temperature is kept within specific limits. This can be difficult to achieve in industrial plants where the operation of large machinery can cause fluctuations in the voltage supply. In the case of resistive heaters a variation of 10% in the supply voltage will generate a 20% variation in the power to the load, resulting in undesirable temperature fluctuations. EFit contains built in compensation that continues to apply stable power with better than ±2% linearity at the boundaries of the load, even during fluctuations in the supply. The result is a reliable, repeatable heating process and high quality end products compliant to demanding heat treatment standards.

Technical Specifications

| General | |

| Directive : | EMC directive 2004/108/EC Low Voltage Directive 2006/95/EC |

| Safety specification: |

EN 60947-4-3:2000 ( 2000-01-12) |

| EMC emissions specification: | EN 60947-4-3:2000 ( 2000-01-12) + EN 60947-4-3:2000/A1:2006 (2006-12-08) + EN 60947-4-3:2000/A2:2011 (2011-09-02) Class A product |

| EMC immunity specification: | EN 60947-4-3:2000 (2000-01-12) EN 60947-4-3:2000/A1:2006 (2006-12-08) EN 60947-4-3:2000/A2:2011 (2011-09-02) |

| Vibration tests: | EN60947-1 annex Q category E |

| Shock tests: | EN60947-1 annex Q category E |

| Approvals | |

| cUL: | UL60947-4-1A and UL60947-1 |

| CE: | EN60947-4-3 and EN 60947-1 A certificate of conformity can be provided on simple request |

| CCC exempt: | Product not listed in catalogue of products subject to compulsory certification |

| China RoHS: |

Restriction of Hazardous Substances compliant |

| Protection: | IP20, According to EN60529 – CE Open type – UL |

| Condition of use | |

| Atmosphere: | Non-corrosive, non-explosive, non-conductive |

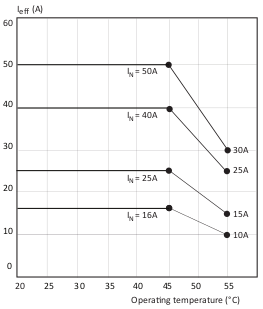

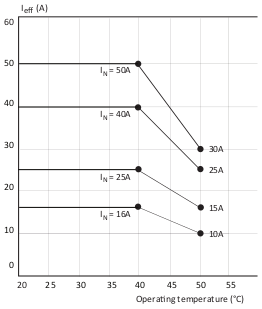

| Operatoring temperature: |

0 to 45°C without derating |

| Storage temperature: |

–25°C to 70°C (maximum) |

| Altitude: |

1000m maximum at 45°C 2000m maximum at 40°C For higher temperature see de-rating curves below |

| Degree of pollution: |

Degree 2 |

| Humidity limits: |

5% to 95% RH (non-condensing) |

|

Current derating curves as a function |

Current derating curves as a function |

| Power | |

| Nominal current: | 16 to 50A |

| Nominal voltage: | 100V to 500V (+10%/–15%). Refer to order code for more details |

| Frequency: | 47Hz to 63Hz |

| Thyristor protection: | High speed fuse |

| Type of loads: | |

| AC51: | Pure resistive |

| AC56a: | Transformer Primary |

| AC55b: | Short wave infra-red |

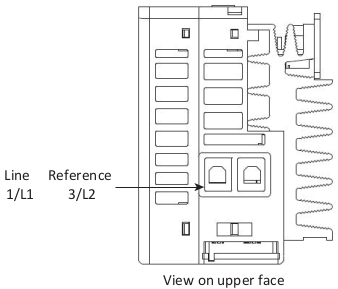

| Power terminals: | Safe cage type, cable size 1.5 to 16mm² tightening torque 2.3Nm (20.4 lb.In) |

| Safety earth screw terminal: | Cable size 1.5 to to 16mm² tightening torque 2.3Nm (20.4 lb.In) |

| Control | |

| Supply of electronics: | Self powered product: 100V ac to 500V ac |

| Auxiliary supply: | 115V ac or 230V ac Auxiliary supply must be in phase with the line. The control circuit shall be protected by a ATM2 fuse rated 600V ac/dc, 2A, 100kA |

| Control setpoint: | Either analogue (analogue input or potentiometer) or logic |

| Analogue input signal: | |

|

DC voltage: |

0-5V, 0-10V, Input impedance 100k ohms |

| DC current: | 4-20mA 250 ohms Burden resistor 250 ohms |

| Potentiometer: | A ‘5V user’ voltage is available between terminals 5 and 7 to be used with an external potentiometer of 10Kohm. One potentiometer per unit should be used |

| Logic: | Contact for On/Off logic operation |

| Control terminals | Plug-in connector 0.5 to 2.5mm² (24 to 12AWG) cables Tightening torque 0.6 Nm (5.31 lb.In) |

| Control Performance | |

| Linearity: | Better than ±2% of the full range |

| Stability: | Better than ±2% of the full range with constant resistance Automatic compensation for supply fluctuation (variation: between –10% and +10% of the nominal voltage). |

| Firing modes: | |

| Burst: | Burst variable (16 periods) Single cycle Advanced single cycle |

| Phase angle: | With or without current limit |

|

|

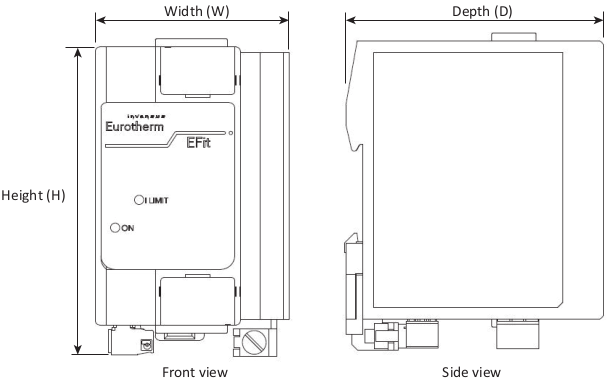

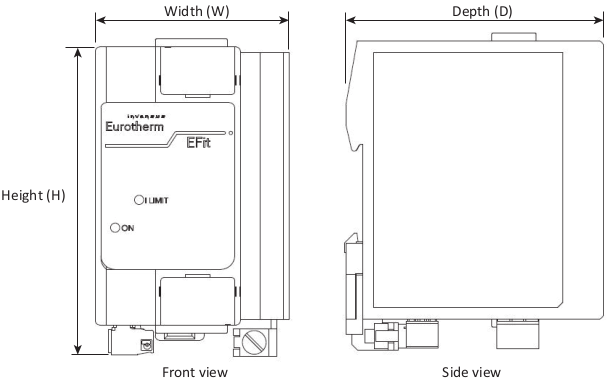

Mechanical Details

| Model | Height | Width | Depth | Weight | Mounting |

| 16A | 115mm | 52.5mm | 92.5mm | 0.55kg | DIN rail |

| 25A | 115mm | 70mm | 92.5mm | 0.7kg | DIN rail |

| 40A | 115mm | 105mm | 92.5mm | 0.9kg | DIN rail |

| 50A | 115mm | 122.5mm | 92.5mm | 1.2kg | DIN rail |

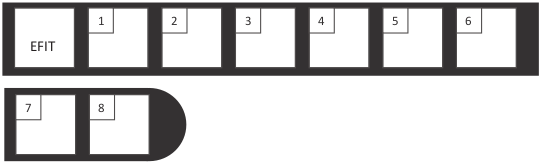

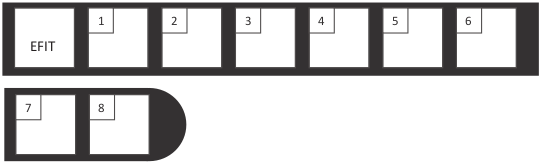

Order Codes

| Basic Product |

| EFIT | Basic SCR Power Controller |

| 1 | Current |

| 16A | 16 amps |

| 25A | 25 amps |

| 40A | 40 amps |

| 50A | 50 amps |

| 2 | Voltage |

| 100V | 100 volts |

| 115V | 115 volts |

| 200V | 200 volts |

| 230V | 230 volts |

| 240V | 240 volts |

| 277V | 277 volts |

| 380V | 380 volts |

| 400V | 400 volts |

| 415V | 415 volts |

| 440V | 440 volts |

| 480V | 480 volts |

| 500V | 500 volts |

| 3 | Input |

| 0V5 | 0–5V dc |

| 4mA20 | 4–20mA |

| 0V10 | 0–10V |

| 4 | Firing Mode |

| FC | Fast cycle |

| FC1 | Single cycle |

| SCA | Advanced single cycle |

| PA | Phase angle |

| 5 | Language |

| ENG | English |

| FRA | French |

| GER | German |

| 6 | Supply |

| SELF | Self-powered |

| 115V | Auxiliary 115V |

| 230V | Auxiliary 230V |

| 7 | Current Limit |

| XX | Without current limit |

| CL | With current limt (only with Phase angle) |

| 8 | Fuse |

| NOFUSE | Without fuse |

| MSFUSE | Fuse with microswitch |

| FUSE | Fuse without microswitch |

Temperature Controllers:

Process Application Control

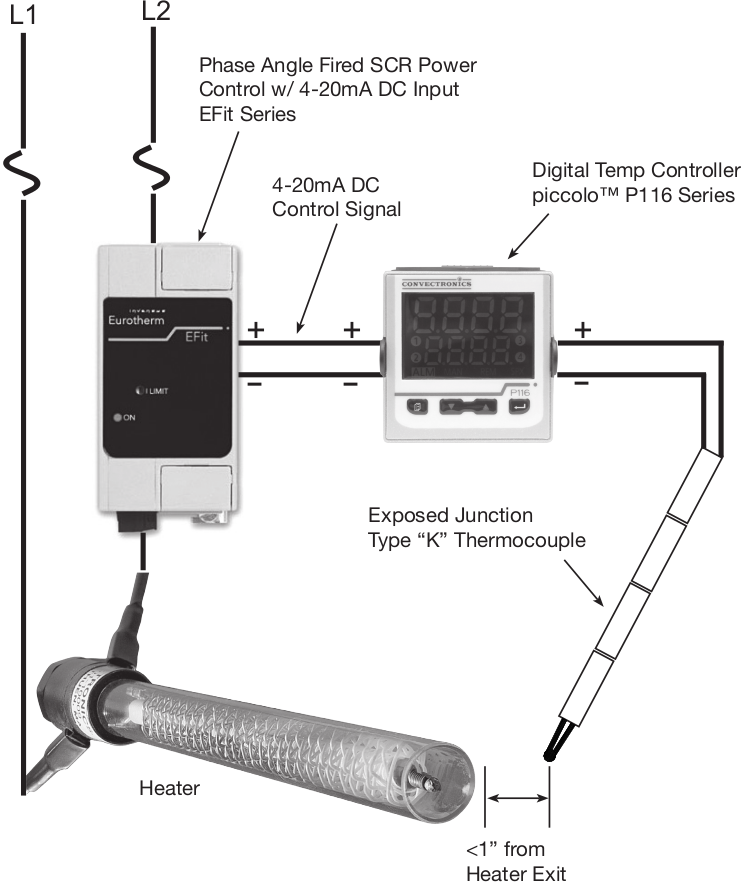

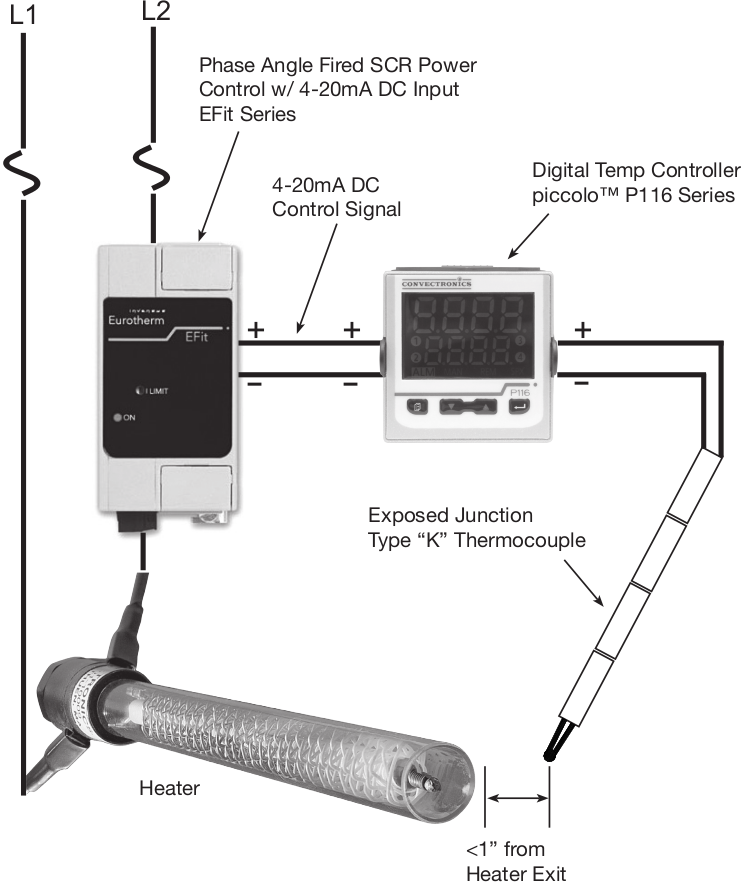

Whether it is Open-Loop or Closed-Loop Control, a good Control System is critical for long heater life.*

Here we demonstrate a Closed-Loop (Feedback) Control Set-up ~

Generally considered the optimal method, a closed-loop heater control system uses a power controller, temperature controller, and thermocouple to provide a constant output temperature, regardless of changes in airflow.

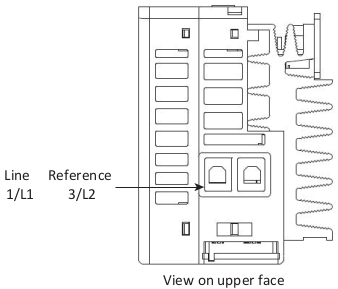

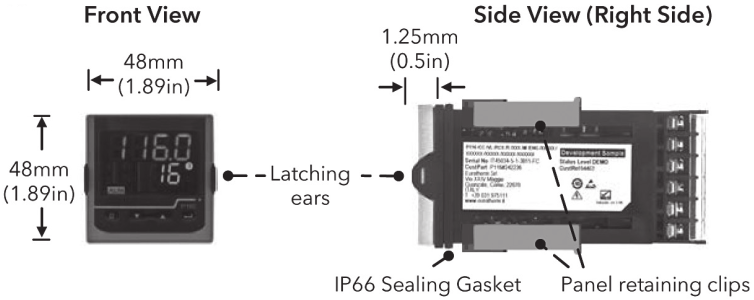

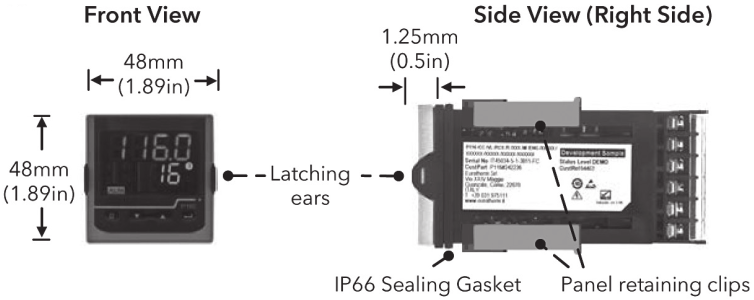

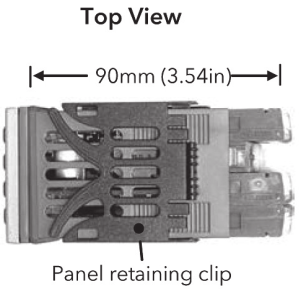

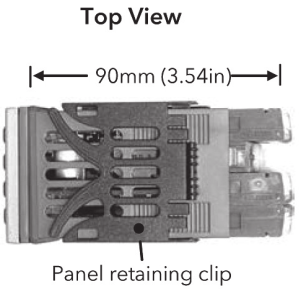

P116 Dimensions

General views of the controllers are shown below together with overall dimensions.

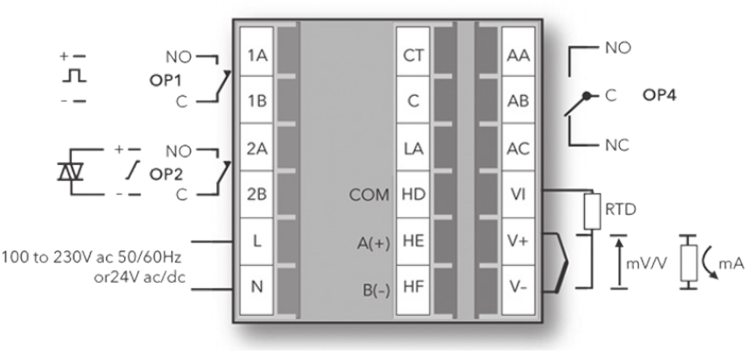

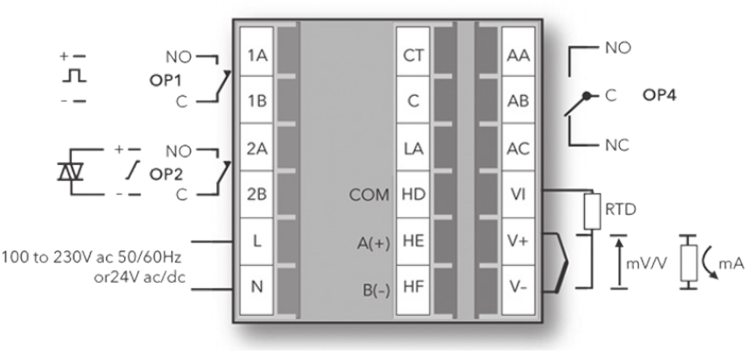

P116 Rear Terminals

Eurotherm piccolo™ controllers offer precision PID control of temperature and other processes with many advanced features not normally found in this class of controllers.

Designed to offer outstanding performance in an affordable package providing a complete solution for a wide variety of applications, this range guarantees extremely easy access to

parameterization and operation in a high quality unit.

Despite their advanced features, the controllers are easy to use and apply and may be customized for ease of operation. Full autotune is provided.

High quality and high reliabilty

The piccolo controller is a high quality and high reliability

unit from a world leading manufacturer with global

support and service facilities. A 3 year warranty is pro-

vided as standard.

Ramp-soak timer and soft start

A ramp soak timer is provided for time based profiling

of temperature sequences. These can be used to

gradually vary the temperature in a control zone before

maintaining it at a defined level, and is typically used to

avoid the dangers of damage due to thermal shock.

Energy usage estimation

The piccolo controller allows estimation of energy

usage to provide basic data for evaluating energy

saving control strategies for continuous improve-

ment and Kaizen techniques.

Overshoot elimination

The Eurotherm unique cutback system ensures pre-

cise control to setpoint and when correctly tuned

inhibits temperature overshoot.

P116 Rear Terminals

-

Plastic Processing Control

The precision PID controller is used to ensure

uniform heating of the material to avoid material

derogation, undue strain on the extruder

components and improve process reliability.

Can be used to consolidate functions and replace

several interconnected devices to chillers, including

an external timer. -

Incubators

-

Food and Beverage

The simple timer may be used to control

batch operations, e.g., food ovens, fryers

and sterilizers. -

Furnaces, Ovens & Kilns

Well adapted for firing ceramics and heat

treating complex parts. -

Laboratory Equipment

| Environmental Performance | ||

|---|---|---|

| Temperature Limits Operation: | 0 to 60°C | |

| Storage: | -10 to 70°C | |

| Humidity Limits Operation: | 0 to 90% RH non condensing | |

| Storage: | 5 to 90% RH non condensing | |

| Panel Sealing: | IP65 | |

| Shock: | BS EN61010 | |

| Vibration: | 2g peak, 10 to 150Hz | |

| Altitude: | < 2000 meters | |

| Atmospheres: | Not suitable for use in explosive or corrosive atmosphere | |

| Electromagnetic Compatibility | (EMC) | |

| Emissions and Immunity: | BS EN61326 | |

| Electrical Safety | ||

| (BS EN61010): | Installation cat. II; Pollution degree 2 | |

| INSTALLATION CATEGORY II | The rate impulse voltage for equipment on nominal 230V mains is 2500V | |

| POLLUTION DEGREE 2 | Normally, only non-conductive pollution occurs. Occasionally however, a temporary conductivity caused by condensation shall be expected. | |

| Physical | ||

| Panel Mounting: | 1/16 DIN | |

| Weight: | 250g | |

| Panel Cut-Out Dimensions: | 45mm W x 45mm H | |

| Panel Depth: | 90mm | |

| Operator Interface | ||

| Type: | LED | |

| Main PV Display: | 4 digits, green | |

| Secondary Display: | 4 digits, amber | |

| Status Beacons: | Units, outputs, alarms, active setpoint | |

| Power Requirements | 100 to 230 ±15% 48 to 62 Hz, max 6W 24V ac, -15%, +10% 24V dc, -15% + 20% ±5% ripple voltage Max 6W |

|

| Approvals | CE, cUL listed (File ES7766) Suitable for use in Nadcap and AMS2750E applications under Systems Accuracy Test calibration conditions Other standards pending |

|

| Process Variable Input | ||

| Calibration Accuracy: | <±0.25% of reading ±1LSD Quoted over full ambient operating range and for all input linearisation types |

|

| Sample Rate: | 4 Hz (250ms) | |

| Resolution (µV): | <0.5µV with 1.6sec filter | |

| Resolution (effective bits): | >17 bits | |

| Linearisation Accuracy: | <0.1% of reading | |

| Drift with Temperature: | <50ppm (typical) <100ppm (worst case) | |

| Common Mode Rejection: | 48-62 Hz, >-120dB | |

| Series Mode Rejection: | 48-62 Hz, >-93dB | |

| Input Impedance: | 100MΩ | |

| Cold Junction Compensation: | >30:1 rejection of ambient change | |

| Cold Junction Compensation: | >30:1 rejection of ambient change | |

| Cold Junction Compensation: | >30:1 rejection of ambient change | |

| Cold Junction Accuracy: | <±1°C at 25°C ambient | |

| Linear (process) Input Range: | -10 to 80mV, 0 to 10V with 100K/806 external divider module | |

| Thermocouple Types: | K, J, N, R, S, B, L, T, C | |

| Resistance Thermometer Types: | 3-wire Pt100 DIN 43760 | |

| Bulb Current: | 0.2mA | |

| Lead Compensation: | No error for 22 ohms in all leads | |

| Input Filter: | Off to 59.9s | |

| Zero Offset: | User adjustable over full range | |

| User Calibration: | 2-point gain & offset | |

| OP 4 Relay | ||

| Type: | Form C (changeover) | |

| Rating: | Min 100mA @ 12V dc, max 2A @ 264V ac resistive | |

| Functions: | Control outputs, alarms, events | |

| Logic Output Module | ||

| Rating: | ON 12V dc @ <44mA; OFF <300mV @ 100µA | |

| Isolation: | None from PV or system, 264V ac double insulated from PSU and communications | |

| Functions: | Control outputs, alarms, events | |

| Relay Output Channels | ||

| Type: | Form A (normally open) | |

| Rating: | Min 100mA @ 12V dc, max 2A @ 264V ac resistive | |

| Functions: | Control outputs, alarms, events | |

| Analogue Output - OP2 | Voltage output can be achieved by external adaptor | |

| Rating: | 0-20mA into <500Ω | |

| Accuracy: | ±(<1% of Reading + <100µA) | |

| Resolution: | 13.5 bits | |

| Isolation: | 264V ac double insulated from PSU and communications | |

| Functions: | Control outputs, retransmission | |

| Software Features - Control | ||

| Number of Loops: | 1 | |

| Loop Update: | 250ms | |

| Control Types: | PID, ON/OFF | |

| Cooling Types: | Linear, fan, oil, water | |

| Modes: | Auto, manual, standby | |

| Overshoot Inhibition: | High, low | |

| Software Features - Alarms | ||

| Number: | 3 | |

| Type: | Absolute high & low, deviation high, low or band | |

| Latching: | Auto or manual latching, non-latching | |

| Output Assignment: | Relay and digital output | |

| Other Status Outputs - Functions: | Including sensor break, timer status, loop break, heater diagnostics | |

| Timer - Modes: | Dwell when setpoint reached; Delayed control action, Soft start limits power below PV threshold | |

| Current Monitor - Alarm Types: | Over current, SSR short circuit, SSR open circuit | |

| Current Monitor - Indication Type: | Flashing Beacon | |

| Special Features: | Energy monitoring, recovery point | |